Waste plastic recycling pyrolysis plant

Waste Tire/Plastic Pyrolysis Plant / Chat on line / Give me a price / Date:2018-08-09

Waste plastic in our dailylife

Waste plastic in our dailylife

The plastic raw material is defined as a synthetic or natural high molecular polymer which can be kneaded into various shapes to finally maintain the shape of the material or plastic material. Due to its high plasticity and low cost, plastic products exist in all aspects of our lives. While bringing convenience to our lives, there is also a large amount of waste plastic produced every year. It is understood that in 2011, the amount of waste plastics produced in China was about 28 million tons, and in 2012 it was 34.13 million tons. The storage, transportation and processing of these waste plastics, pending the application and post-treatment of the discarded plastic raw materials, will inevitably damage the environment and endanger the health of the people.

DOING waste plastic recycling pyrolysis plant

DOING waste plastic recycling pyrolysis plant

The waste plastic recycling pyrolysis plant is an environmentally friendly system that uses continuous liquefaction technology and catalytic decomposition reactions to convert waste plastics into renewable resources such as pyrolysis oil, carbon black, and combustible gases. The final product can be used directly in diesel engines and generators, or in our refineries to produce premium diesel and gasoline. Other names for waste plastic recycling pyrolysis plant: waste plastic pyrolysis machines, plastics to oil machines/equipment, waste plastics to fuel conversion equipment, plastic oil equipment, etc.

The specific workflow of the waste plastic recycling pyrolysis plant is as follows:

Waste plastic recycling pyrolysis plant working process

Waste plastic recycling pyrolysis plant working process

1. The waste plastic is sent to the reaction vessel through an automatic feeder device, and the reaction vessel is heated.

2. When the temperature of the reactor reaches about 280 degrees, the waste plastic begins to crack out the oil and gas.

3. After the oil and gas enters the condensing system, it is liquefied into heavy oil and flows into the oil tank.

4. Degrease and desulfurize the heavy oil in the tank, and finally get fuel.

5. Exhaust gas generated during the combustion process will be recovered by the pyrolysis plant for the heated fuel used in the reactor.

6. The carbon black generated during the combustion process will be discharged outside the furnace through the underground sealing slag discharge channel to avoid secondary pollution to the environment.

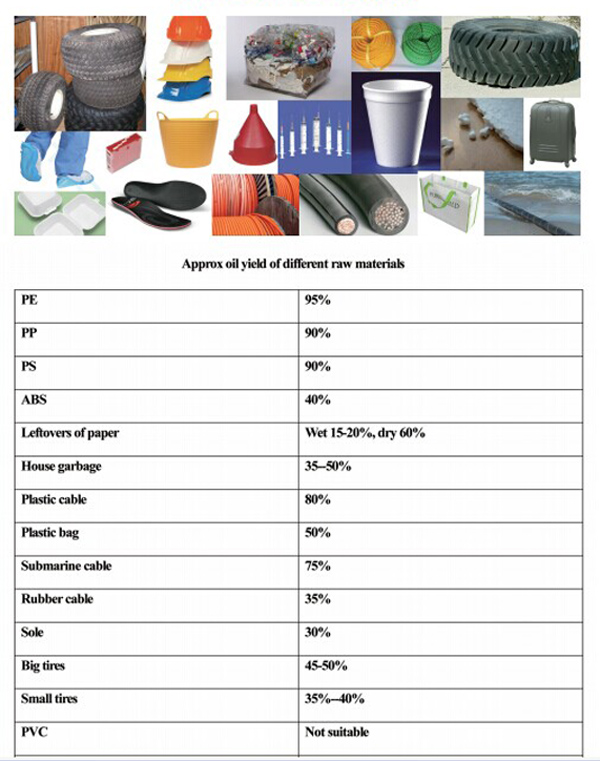

Fuel, carbon black, and flammable gases can be obtained through this process. Due to the different materials of waste plastics, there is no uniform standard for oil yield. To this end, we have classified waste plastics and summarized the following common waste plastics oil yields:

Different kinds waste plastic oil yield

Different kinds waste plastic oil yield

Our company has a strong team of experts who specialize in research and development of various environmentally friendly equipment, especially pyrolysis plant, including tire pyrolysis plant, rubber pyrolysis plant and plastic pyrolysis plant. With the advancement of technology With the growth of foreign trade business, DOING company has opened up a broader international market. Our products have been exported to the United States, Europe, South Korea, the Middle East, Southeast Asia and other dozens of countries and regions. Our thoughtful service is highly appreciated by foreign governments and customers. DOING company promises that we will always provide customers with high quality delivery and factory output. The reason why DOING company's waste plastic recycling pyrolysis plant is so popular is mainly due to the following advantages of the equipment:

Mexican customer‘s 10 sets waste plastic pyrolysis plant installed

Mexican customer‘s 10 sets waste plastic pyrolysis plant installed

1. It adopts 16mm Q245R standard boiler plate steel, which is resistant to high temperature and high pressure.

2. Unique 3-step seamless welding process for longer life.

3. Adopt the most advanced and best condensing device in the current oil industry. Ensure that oil and gas can be fully cooled and the oil yield is high.

4. The waste plastic recycling pyrolysis plant is equipped with safety devices such as oil-water separator, vacuum device and oil separator.

Nowadays, the foreign market for waste plastic recycling pyrolysis plant is very hot. In addition to the above-mentioned advantages of our waste plastic pyrolysis plant, it is also influenced by the previous plastic limit order-not allowed to import foreign waste plastics. The introduction of this policy is another important factor that has made the foreign waste plastic recycling pyrolysis plant market very active. Our equipment not only solves thousands of tons of waste plastics that are a headache for our customers, but our equipment is environmentally friendly.

As a veteran in the field of environmental protection, each of our products has complete industrial waste treatment equipment. Our machines not only convert waste plastics,but can also convert waste rubber, waste tires, municipal solid waste, medical waste, into useful fuel oils that can recycle waste and reduce waste. Our machines also feature state-of-the-art flue gas systems and dust removal systems to reduce air and environmental pollution. Therefore, DOING company's waste plastic recycling pyrolysis plant is a machine that is very friendly to our environment.

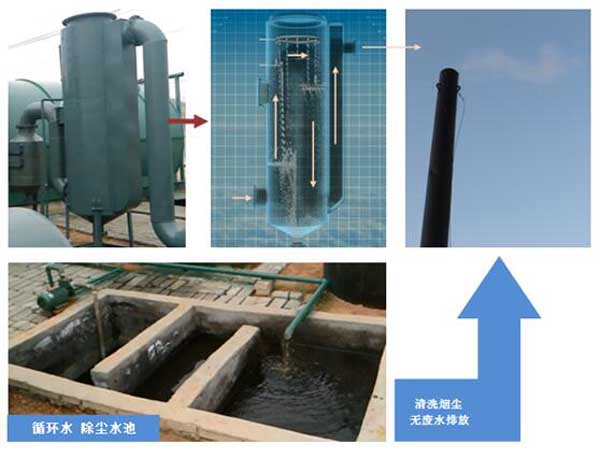

No harmful gas exhausted

No harmful gas exhausted

As for DOING company's machines, plastics are converted into oil, and there is very little exhaust gas generated in the process. Before discharge, the exhaust gas should be treated by a dust removal system equipped with a water ring and a magnetic ring to reduce dust and sulfide. In addition, for wastewater, the water produced in the water-soluble and dedusting system and the water produced during the pyrolysis process are used to effect water circulation, and finally discharged after filtration. DOING company has done its utmost to manufacture pyrolysis plant that is harmless to our environment. If you have any interest, please feel free to click on DOING comapny, we always provide the best waste plastic recycling pyrolysis plant and other machines.

DOING waste plastic recycling pyrolysis plant environmental protection system

DOING waste plastic recycling pyrolysis plant environmental protection system

In addition, DOING company provides thoughtful after-sales service:

We promise to respond to your inquiry as soon as possible. If there are some troublesome problems around me, the reply will be delivered within 24 hours.

The master plan of the project will be given within one day after we have agreed on the details and signed the contract.

You will receive the basic layout within two days of the transfer.

The specialist will arrange for your factory to complete the installation and train your workers.

We will make regular phone calls to ensure that your device has no problems or that problems are discovered in a timely manner and resolved immediately.

We always provide you with lifetime maintenance.