What fuel can be used as heating fuel for power plants? How to produce it?

Industry News / Chat on line / Give me a price / Date:2023-10-17

Power plants usually use heating fuel such as coal, natural gas, oil, etc., but these heating fuel is high cost. Therefore, many power plants are starting to use alternative heating fuels such as pyrolysis oil to replace traditional heating fuels. This article will introduce you to pyrolysis oil and how to produce it.

The pyrolsis oil of waste matter

The pyrolsis oil of waste matter

Pyrolysis oil refers to fuel oil from waste matter such as waste plastic, used tires, municipal waste, oil sludge etc., which can be converted through pyrolysis. So, how to produce pyrolysis oil from waste matter with pyrolysis equipment, the pyrolysis process is introduced below:

1. Pre-treatment:

Firstly, the waste matters should be pretreated. Processing waste matter in advance can reduce the amount of heat required for pyrolysis and improve efficiency. For waste plastic, it needs to be dry, not too much moisture. For waste tire, it can be directly whole into the pyrolysis equipment or shredded into rubber powder, it depends on the type of the pyrolysis plants. ((DOING batch type can process the whole tire, while the semi-continuous and the continuous type only can process rubber power.)

2. Pyrolysis:

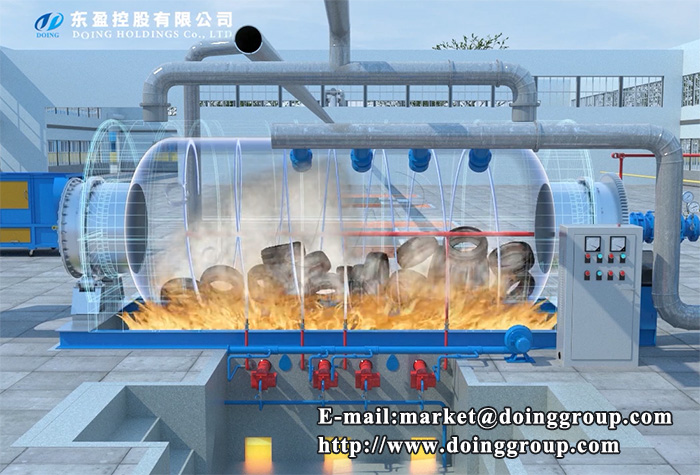

The pretreated waste plastic or tire is fed into the pyrolysis chamber of the pyrolysis equipment, and then heated under anaerobic conditions (no air). The heating process causes the long-chain polymers in the waste plastic or tire to break into smaller molecules, which are then converted into oil-gas and solid carbon black.

The pyrolysis process of waste matter

The pyrolysis process of waste matter

3. Separation & Liquefaction:

Oil-gas can be condensed and separated into liquid and non-condensable gas through multiple industrial condensers. The liquefied part is pyrolysis oil, which can be directly used as fuel for industrial plants. At the same time, pyrolysis oil can be further processed to generate energy. For example, it can be converted into diesel through DOING oil refining equipment for use in diesel generators or mining and agricultural machinery. The non-condensable fraction contains flammable gases that can be used for power generation or other purposes.

The condense system of DOING pyrolysis equipment

The condense system of DOING pyrolysis equipment

The above is an introduction to the production process of pyrolysis oil. The pyrolysis raw materials are easy to obtain with low cost, so it is understandable that pyrolysis oil has become a popular heating fuel for power plants. However, the temperature and other operating parameters of the pyrolysis equipment will affect the yield and quality of the pyrolysis oil. In order to obtain high-quality pyrolysis oil, it is necessary to choose mature pyrolysis technology and experienced pyrolysis equipment suppliers. DOING Group has been engaged in pyrolysis oil production pyrolysis equipment for 13 years. If you want to know more details, you can contact us for free.