What's the capacity of waste oil refining to diesel plants and their cost?

Industry News / Chat on line / Give me a price / Date:2023-11-02

DOING waste oil refining to diesel plants have different processing capacities ranging from mini-scale (100KG to 3 tons per day) to middle-scale (5 tons, 7 tons, 10 tons, and 15 tons per day), as well as larger-scale (20 tons and 30 tons per day) plants. The cost of these plants varies depending on the capacity and configurations chosen.

Various capacities of DOING waste oil refining to diesel plants

Various capacities of DOING waste oil refining to diesel plants

Here is a breakdown of the capacity and cost of DOING waste oil refining to diesel plants:

1. Mini-scale plants: These plants are mainly used for testing purposes and have capacities ranging from 100KG to 3 tons per day. The cost of mini-scale plants ranges from 12,000 to 40,000 dollars.

2. Middle-scale plants: These plants have capacities of 5 tons, 7 tons, 10 tons, and 15 tons per day. The cost of middle-scale plants ranges from 50,000 to 100,000+ dollars.

3. Larger-scale plants: These plants have capacities of 20 tons and 30 tons per day. The cost of larger-scale plants ranges from 200,000 to 300,000+ dollars.

Under the above capacity, we also have two types of waste oil refining to diesel plants available for the choice: the liquid catalyst type and the solid catalyst type. (Recommended reading: What are the options for waste oil refining to diesel plants)

Two types of DOING waste oil refining to diesel plants

Two types of DOING waste oil refining to diesel plants

Over the past 13 years, DOING has reached friendly cooperation with hundreds of customers in various regions on our waste oil refining to diesel plants, which not just because we offer a variety of options, but more importantly because of the excellent performance and quality of our waste oil refining to diesel plants:

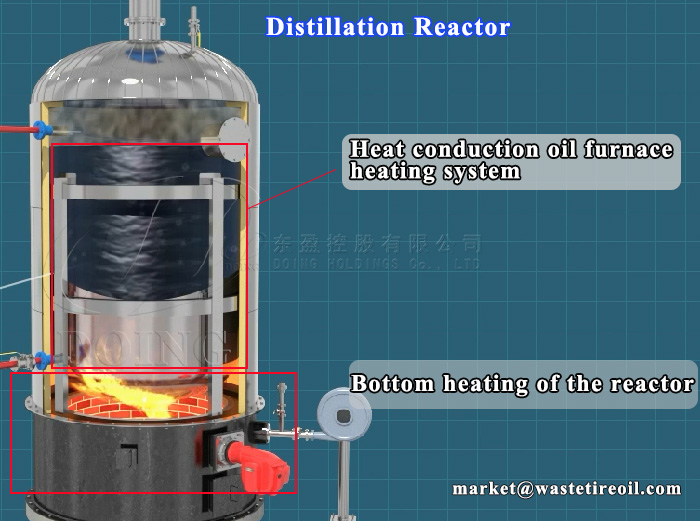

1. Our waste oil refining to diesel plant adopts double heating system- fuel heating and coil heater heating which can greatly improve the distillation efficiency. Except for the fuel heating directly from the bottom of the distillation reactor, the inner coil heater can make the heating more evenly and faster.

Double heating system of DOING waste oil refining to diesel plant

Double heating system of DOING waste oil refining to diesel plant

2. In order to ensure safety, our waste oil refining to diesel plant is equipped with pressure gauge, temperature controller and safety valve at each key position, so that workers can control the operation of any part at any time. And our newly designed waste oil refining to diesel plant puts the catalyst tower above the cooling system directly, which can enhance the working efficiency and safety.

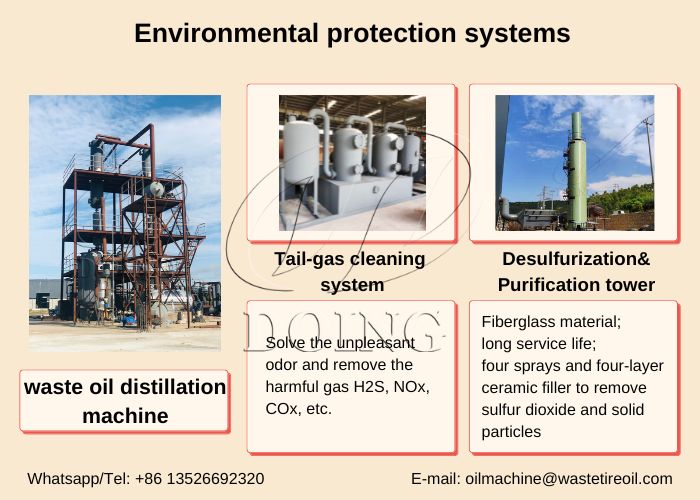

3. Our waste oil refining to diesel plant is equipped with environmental protection systems, which won't produce any pollution to the environment during the working process. For example, our tail gas cleaning system can fully purify the exhaust gas to meet the emission standard and won't produce any air pollution.

Environmental protection systems of DOING waste oil refining to diesel plants

Environmental protection systems of DOING waste oil refining to diesel plants

In a word, DOING waste oil refining to diesel plants can provide you with multiple choices at a reasonable cost, so if you are interested in our waste oil refining to diesel plants, please do not feel hesitant to contact us to get a detailed offer.