What kinds of polystyrene waste can be recycled by pyrolysis process?

Industry News / Chat on line / Give me a price / Date:2025-09-18

Polystyrene (PS), a common thermoplastic with high hydrocarbon content. Its ability to completely decompose under controlled thermal conditions makes it well-suited for pyrolysis. Pyrolysis can recover valuable fuels, carbon black, and combustible gases from various types of polystyrene waste, including those that cannot be mechanically recovered due to contamination, mixing, or degradation. Below is a detailed breakdown of recyclable polystyrene waste types, plus how DOING waste plastic pyrolysis equipment optimizes their conversion for efficiency and profit.

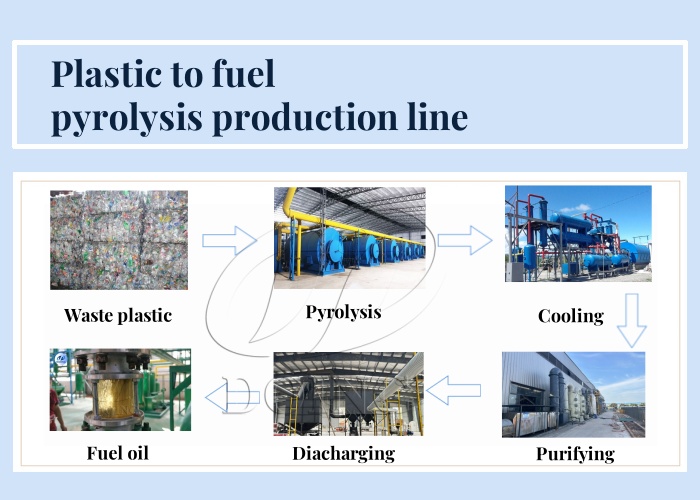

DOING waste plastic pyrolysis equipment process

DOING waste plastic pyrolysis equipment process

Types of Polystyrene Waste Suitable for Pyrolysis Process

1.Expanded Polystyrene (EPS) – "Foam" or "Styrofoam"

Characteristics: Lightweight (95% air) but difficult to degrade. Its low density makes it easy to crush and heats evenly during the pyrolysis process, resulting in a high oil yield.

Common Sources:

Packaging materials: EPS foam used for electronics packaging(e.g., TV, laptop foam inserts, appliance buffers), and food delivery.

Disposable EPS items: Foam cups, plates, disposable thermal containers (takeout boxes, coffee cups ), and single-use ice cube trays.

2.Extruded Polystyrene (XPS)

Characteristics: Excellent thermal insulation and water resistance

Common Sources:

Construction insulation: EPS foam boards for roofs, floors, and underground pipelines and building insulation (free of adhesives or fire-retardant additives like hexabromocyclododecane/HBCD—additives contaminate pyrolysis products).

Pyrolytically recyclable plastic waste types

Pyrolytically recyclable plastic waste types

3.Rigid Polystyrene (RPS)

Characteristics: Denser and more rigid than EPS, used in durable products—its higher hydrocarbon concentration yields more pyrolysis oil.

Common Sources:

Consumer goods: Broken or outdated polystyrene toys, plastic cutlery (non-colored or lightly colored), and cosmetic packaging (e.g., cream jars, lipstick cases).

Industrial scraps: RPS offcuts from plastic manufacturing (e.g., injection molding scraps, sheet trimming waste)—these are pure, uncontaminated, and require minimal pre-treatment.

Household items: Polystyrene storage boxes, CD/DVD cases (after removing paper labels), office supplies and lightweight furniture parts (e.g., chair armrests, shelf inserts).

4.High Impact Polystyrene (HIPS)

Characteristics: Tougher than RPS due to added rubber (usually polybutadiene).

Common Sources:

Appliance housings, toys, medical devices, food packaging.

Pyrolysis Consideration: Slightly lower oil yield than RPS due to rubber content. Produced oil with some aliphatic compounds and char. Still highly recyclable via pyrolysis.

Why Use Pyrolysis Process for Polystyrene Waste Recycling?

Process of DOING Pyrolysis Equipment for Polystyrene Waste

1. Pre-treatment: Waste polystyrene is pre-processed to ensure that it is free of impurities and moisture.

2. Pyrolysis: The waste is heated in an oxygen-free environment, breaking down the polymers into smaller molecules.

3. Condensation: The gaseous products are cooled and condensed into liquid fuel oil, while solid carbon black and gases are collected.

DOING waste plastic pyrolysis equipment process

DOING waste plastic pyrolysis equipment process

DOING Polystyrene Waste Plastic Pyrolysis Process Benefits

1. Efficiency: The pyrolysis process breaks down polystyrene into usable by-products efficiently, reducing the overall waste.

2. Sustainability: It helps reduce environmental pollution by converting plastic waste into renewable energy, such as fuel oil, which can be used in various industrial applications.

3. Profitability: The by-products from the pyrolysis process—such as fuel oil, carbon black, and gas—can be sold or utilized, making the process a lucrative investment.

Pyrolysis oil: PS-derived oil has a high calorific value (43–45 MJ/kg) and is rich in styrene—usable as industrial fuel (for boilers, heavy oil generators) or refined into diesel for heavy machinery or diesel generators. DOING multi-stage condenser captures 98% of oil vapors, minimizing waste.

Syngas: Uncondensed syngas (methane, ethylene) is reused to heat the reactor, cutting external energy costs by 30%.

Carbon black: Small amounts of carbon black (5–8% of input) are collected and sold as a filler for rubber or ink—adding extra revenue.

DOING waste plastic pyrolysis equipment product application

DOING waste plastic pyrolysis equipment product application

Recycling polystyrene waste with DOING waste plastic pyrolysis equipment optimizes each step to maximize yield, ensure compliance, and create profits. For businesses looking to transform polystyrene waste into a valuable resource, DOING customized solutions are a reliable choice. Contact us today!