Stop Losing Money on Plastic Landfill Disposal | Pyrolysis Profit Solutions

Industry News / Chat on line / Give me a price / Date:2025-09-26

Every year, over 350 million metric tons of plastic waste are generated globally, yet less than 10% is recycled. In countries like India, Indonesia, United States, Vietnam, Malaysia, Vietnam, China and Turkey, Thailand and Nigeria—where landfill remains the default disposal method—millions of dollars in potential revenue vanish alongside environmental degradation. Businesses relying on outdated plastic disposal practices aren't just harming ecosystems; they're sacrificing profitability.

The Hidden Cost of Landfilling Plastic

Landfills burden companies with rising disposal fees, regulatory penalties, and wasted feedstock. For instance, Indonesia discards approximately 1.3 million tons of recyclable plastic annually through landfills—a loss exceeding $200 million in recoverable materials. Similarly, the U.S. landfills over 27 million tons of plastic yearly, squandering raw materials that could fuel industrial processes.

Disadvantages of waste plastic landfill

Disadvantages of waste plastic landfill

Pyrolysis Technology: Transforming Waste Plastic into High-Value Outputs

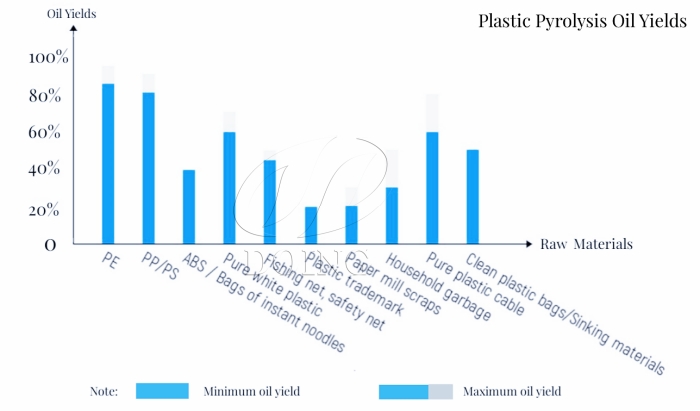

Pyrolysis technology provides a practical and profitable alternative, converting mixed or contaminated plastics (including HDPE,LDPE, PP, PS, ABS, and multi-layer aluminum plastic composites) into:

·PPO Plastic Pyrolysis Oil(alternative industrial heating fuel oil with high calorific value: 8,500–11,428.5kcal/kg, about 38.4 to 45.3 MJ/kg)

·Carbon Black (used in tires, coatings, and construction)

·Syngas (reusable for pyrolysis reactor heating or other boiler heating)

Pyrolysis plant for waste plastic disposal

Pyrolysis plant for waste plastic disposal

Markets like Germany, Russia, Brazil, Mexico, Netherland and Vietnam show growing demand for pyrolysis-derived fuels, with prices for industrial fuel oil averaging $500–$1000 per ton, offering margins up to 30%.

Why Partner with Henan Doing Company about Plastic Pyrolysis?

As a leader in waste plastic pyrolysis machine solutions, Henan Doing Company delivers:

①Material Flexibility: Process hard-to-recycle plastics (e.g., agricultural films, medical plastic waste, organic glass, acrylic, PCB e waste, car bumper, shredded wind turbine fan blades materials, mixed polymers, etc.).

Noted: PVC and PET plastics aren't suitable for pyrolysis.

Recyclable waste plastic for pyrolysis machine

Recyclable waste plastic for pyrolysis machine

②Proven Pyrolysis Technology: Over 100+ countries and regions export experience, have installed successful operational plastic pyrolysis plants in Malaysia, Brazil, Fiji, Korea, Japan, India, China, Vietnam, Haiti, Chile, Poland, Venezuela, etc.

③Turnkey Services: Customized engineering, installation, and ongoing technical support.

Seize the Circular Economy Opportunity to Turn Waste Plastic into Wealth

With landfill bans expanding in the EU, Canada, and Australia, pyrolysis offers compliance and revenue. Even in regions without strict regulations, early adopters gain competitive pricing power in fuel and carbon black markets.

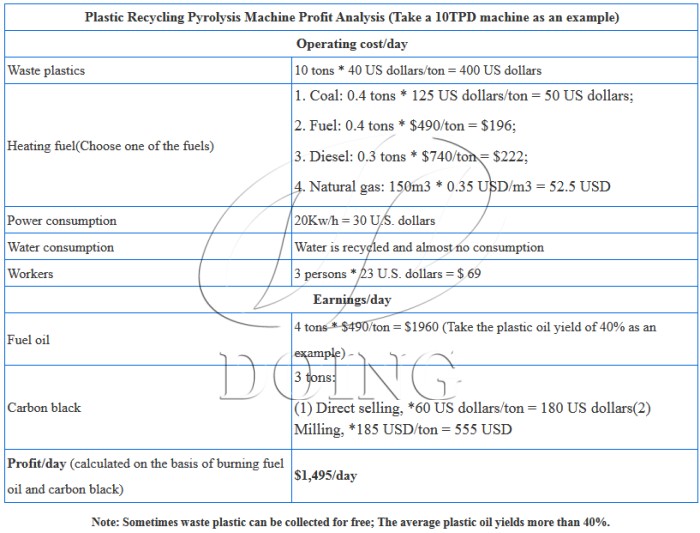

Waste plastic recycling pyrolysis machine profit analysis

Waste plastic recycling pyrolysis machine profit analysis

Stop losing millions to landfills on waste plastic disposal. Henan Doing Company's waste plastic recycling pyrolysis machines help businesses monetize waste streams sustainably. Contact us today for a feasibility analysis tailored to your plastic waste feedstock and local market conditions.