Plastic to oil conversion pyrolysis plant

Waste Tire/Plastic Pyrolysis Plant / Chat on line / Give me a price / Date:2020-08-14

Over the years, faced with the huge accumulation of waste plastics, people have proposed a variety of disposal methods such as burial, burning, transfer and so on. But the solution is contrary to the expected effect, not only the energy use efficiency is low, some will cause more serious environmental pollution.

Waste plastics in our dailylife

Waste plastics in our dailylife

But now people have found a really efficient way to do it – plastic to oil conversion pyrolysis plant. This treatment method is not only economically feasible, but also simple to operate and high energy efficiency. The key is to realize the waste plastic non-pollution recovery and produce alternative heating fuel oil.

Plastic to oil conversion pyrolysis plant picture

Plastic to oil conversion pyrolysis plant picture

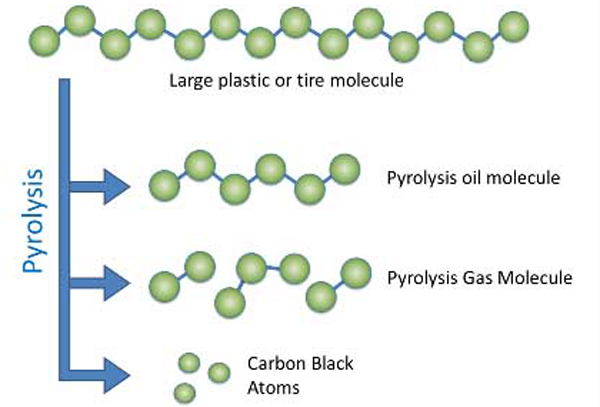

Pyro=heat. Lysis=break down. Pyrolysis is a thermo-chemical reaction, which involves molecular breakdown of larger molecules into smaller molecules in presence of heat. The diagram below shows the pyrolysis process.

Plastic to oil conversion pyrolysis plant pyrolysis process

Plastic to oil conversion pyrolysis plant pyrolysis process

Final products from plastic to oil conversion pyrolysis plant

At high temperatures and without oxygen, waste plastics undergo the above cracking process to produce plastic pyrolysis oil, carbon black and non-condensable gases. Of course, plastic pyrolysis oil is the main product obtained from plastic to oil conversion pyrolysis plant that we want to get.

Plastic pyrolysis oil from waste plastic

Plastic pyrolysis oil from waste plastic

Each product from plastic to oil conversion pyrolysis plant has a wide range of uses in life.

1. Plastic pyrolysis oil

Waste plastic pyrolysis fuel oil usages

Waste plastic pyrolysis fuel oil usages

Plastic pyrolysis oil is widely used as marine boiler fuels, furnace fuels, metallurgical furnaces fuel and other industrial furnace fuels. According to the statistics of the National Bureau of Statistics, China's fuel oil consumption is mainly concentrated in power generation, transportation, metallurgy, chemical, light industry and other industries.

2. The non condensable gas is usually recycled to heat the reactor or collected for other heating use.

3. Carbon black could be made into pellets for burning and heating ,just like coal, or refining for making new rubber products.

Carbon black usage

Carbon black usage

4. Steel wire could be sold to the recycle station or steel mill for remelting.

We have different types of plastic to oil conversion pyrolysis plant, including 500kg, 1T, 5T, 10T, 12T, and continuous plastic to oil machines. Customers can choose according to their actual needs.

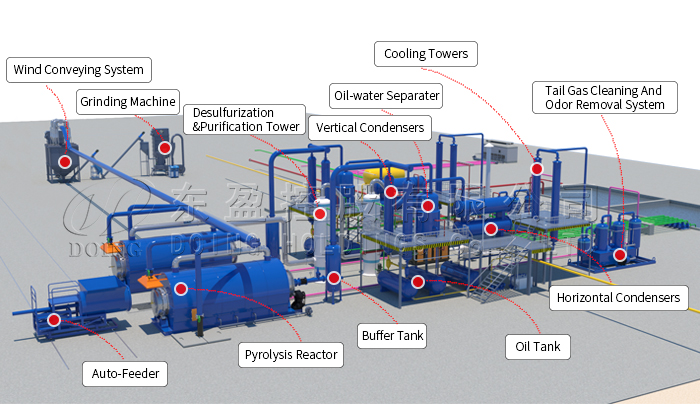

Main parts of DOING company plastic to oil conversion pyrolysis plant

DOING 3D plastic to oil conversion pyrolysis plant Reactor

DOING 3D plastic to oil conversion pyrolysis plant Reactor

Pyrolysis reactor

Pyrolysis reactor is the main part of plastic to oil conversion pyrolysis plant. Our pyrolysis reactor has many advantages. The material of our reactor is Q245R, comparing with Q345R, the tension is better, and easier to be welded for better welding. So it has better expanding and ductility and high temperature resistance, so the service time will increase about 5 to 8 years.

DOING plastic to oil conversation pyrolysis reactor design details

DOING plastic to oil conversation pyrolysis reactor design details

Reducer

The reducer is used to drive the reactor, and it can keep the reactor running smoothly with full raw material loaded. Besides, the spring on the base will buffer the force from the connection between the reducer and the reactor, as as to keep the reactor rotating stably, and prolong the lifetime of the gear.

Reactor door

In order to meet client’s different raw material and different feeding way, the door can be designed as requirement.

Cooling condenser

In addition, our plastic to oil conversion pyrolysis plant include condenser, water seal, oil tank, dust-removal system, etc. Our company can supply the three-in-one design (Condenser, water seal, oil tank), which can reduce shipping cost and short installation time.

Tail gas cleaning and odor removal system

In order to make the tail gas discharged into the air meet the standard, our plastic to oil conversion pyrolysis plant is equipped with tail gas cleaning and odor removal system, so that

Main technical parameters of plastic to oil conversion pyrolysis plant

| Technical parameter of plastic to oil conversion pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Raw material | Waste tyre/plastic | Waste tyre/plastic | Waste tyre/plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 4.4-5.5ton | 5.5-6.6ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

Prepared by customer about plastic to oil conversion pyrolysis plant

| Prepared by customer about plastic to oil conversion pyrolysis plant | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

The main working process of plastic to oil conversion pyrolysis plant

Plstic to oil conversion pyrolysis plant working process

Plstic to oil conversion pyrolysis plant working process

1. If the waste plastic contains high amount of water, for better pyrolysis, the plastic is better to be dried at first before pyrolysis;

2. Then feed the dried plastic waste into the pyrolysis reactor by manual or auto feeding system;

3. Start heating, after pyrolysis reactor temperature increase to the required degree, the oil gas will be generated;

4. Heavy components is sent to the heavy oil tank, and light oil gas will be liquefied and stored in the oil tank.

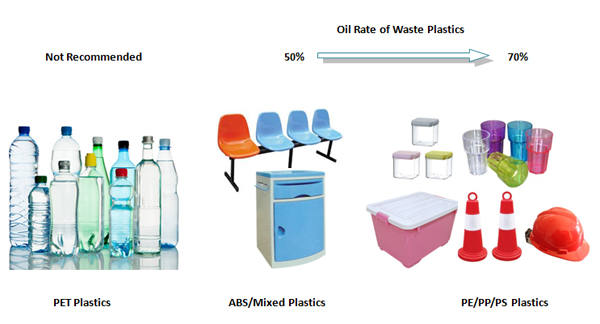

For different waste plastics, the oil yield is also different

Different kinds waste plastic oil yield

Different kinds waste plastic oil yield

| General plastic | |

| Raw material | Oil yield |

| Pure PE plastic | 95% |

| Pure PP plastic | 90% |

| Pure PS plastic | 90% |

| Pure ABS plastic | 40% |

| Pure white plastic sheets | 70% |

| Insatant noodles packing bags | 40% |

| Plastic logo | 20% |

| Paper-mill waste | Dry/60% |

| Wet/15-20% | |

| Plastic household garbage | 30-50% |

| Pure plastic cable sheath | 80% |

| Pure plastic bags | 30% |

| PVC | Not suitable |

| PET | Not suitable |

DOING company Plastic to oil conversion pyrolysis plant has the advantages of excellent quality, high efficiency, safe, low noise, steady and smooth operation, low power consumption, good mixing, high output, good dispersion, energy and space saving, etc. It is a wise decision to choose DOING company when you are purchasing the plastic to oil conversion pyrolysis plant.

First-rate Service of DOING company Environmental Technology

Pre-sales service: DOING company will explain for customers with all details about our high-tech plant.

Production service: Production report is provided during machine production to warrantee the customer get the best quality machine in time.

After-sale service: at least one engineer will be sent to be in charge of installation and commission service, also training the workers is included.

Plastic to oil conversion pyrolysis plant were being installed

Plastic to oil conversion pyrolysis plant were being installed

DOING company is one of the trust worthy plastic to oil conversion pyrolysis plant manufacturers and suppliers with world recognition

1. Our machine always has high usability, durability, efficiency, and safety features and manufactured with the most advanced waste plastic recycling technology.

2. DOING company promises every customer that all of our plastic to oil conversion pyrolysis plant are manufactured with the highest quality materials and parts. If well maintained during the operation, DOING company’s plastic to oil conversion pyrolysis plant can be used year after year.

3. DOING company offers the complete design and implementation of the recycling line and also can provide the custom solutions to satisfy the requirement of your recycling plant.

4. Our products have been sent to more than 60 countries and areas in the world. We have rich exporting experience.

DOING plastic to oil conversion pyrolysis plant project cases in some countries

DOING plastic to oil conversion pyrolysis plant project cases in some countries

To provide the most suitable plastic to oil conversion pyrolysis plant for our customers, DOING company has never stopped updating and upgrading our technology and device.

Welcome to DOING company for buying the plastic to oil conversion pyrolysis plant. Furthermore, we also can supply waste sorting plant and other metal recovery equipment , if you are interested in waste to energy project, please chat us online to find more.