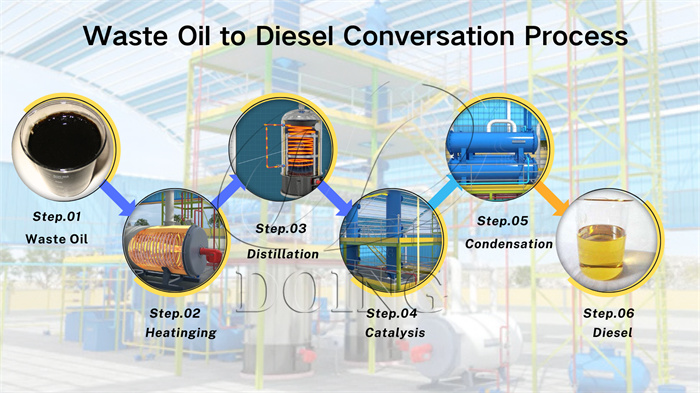

Process flow of waste oil distillation plant to convert waste oil into diesel fuel

Video / Chat on line / Give me a price / Date:2021-05-31

This video introduces the operation process of waste oil distillation plant to convert waste oil into diesel fuel. The raw materials can be tires, plastics, rubber pyrolysis oil, waste engine oil, etc. After these raw materials are refined by waste oil distillation machine, light diesel and asphalt can be obtained.

From the video we can see that the operation process of waste oil distillation machine can be divided into the following steps.

1. Heating pretreatment with heat conducting oil

The heat conducting oil is circulated throughout the system in preparation for subsequent heating.

2. Heating the distillation reactor to produce oil gas

Use heat conducting oil and combustion machine to heat the distillation reactor to produce oil gas from waste oil, which can be condensed into oil through the condensation system (vertical condenser, horizontal condenser). And before the oil gas cooling into diesel fuel, the generated oil gas will be catalyzed by the solid catalysts designed by Henan DOING's engineer team.

Waste oil to diesel distillation plant working process

Waste oil to diesel distillation plant working process

3. Tail gas treatment

Some non-condensable but combustiblee gas can be recovered after being treated by the tail gas cleaning system and directly used to heat the distillation reactor to save fuel.

4. Smoke treatment

The smoke generated during the fuel combustion process can meet the national gas emission standards after being purified by the smoke cleaning system, and will not cause secondary pollution to the environment.

5. Collect the asphalt

After the distillation reaction, the distillation residues in the distillation reactor is asphalt, which can be collected for road paving or sold to an asphalt plant for further refining.

In addition to the 3D animation video we saw, Doing Group also provides project case videos for reference. If you are interested in waste oil distillation machine, welcome to consult us feel free.