Can you get money out of old tires?

FAQ / Chat on line / Give me a price / Date:2025-05-29

In people's traditional mindset, waste is often seen as useless and destined for disposal. However, some wastes still hold value for reuse, and old tires are a prime example. Today, let's explore the business opportunities in recycling old tires.

The Current Landscape of Old Tire Recycling

Currently, China generates the largest number of old tires globally, with approximately 260 million units produced annually, weighing nearly 9.5 million tons. The annual growth rate of old tire generation is between 8% and 10%. Yet, the recycling rate remains at only about 50%. This not only leads to a massive waste of resources but also causes severe environmental pollution. Old tires, if discarded indiscriminately, occupy land, breed mosquitoes, and spread diseases. When burned in the open, they release large amounts of harmful gases, posing significant threats to air, soil, and water. Therefore, recycling old tires holds immense importance for both resource conservation and environmental protection.

Globally, the issue of old tire pollution is equally pressing, such as Kuwait, Indonesia, Laos, Nigeria, India, Vietnam, South Africa, Canada, Australia, etc. Many countries are actively seeking effective solutions to address the old tire problem. Against this backdrop, tire recycling businesses, especially pyrolysis recycling, present promising opportunities.

Waste tire pyrolysis raw materials

Common Methods of Recycling Old Tires for Profit

Old Tire Retreading: Retreading involves refurbishing worn tires to extend their lifespan. However, this method has relatively low profit margins and faces limitations in market demand. The process is also relatively complex and requires strict quality control. Poorly retreaded tires may pose safety risks, which has restricted the large-scale development of the retreading industry.

Producing Rubber Powder from Tires: Rubber powder derived from old tires has various applications, such as in rubber products, plastics, coatings, and construction materials. In recent years, however, the rubber powder market has become oversaturated. Additionally, the high costs of rubber powder production equipment have led to declining profit margins, making it less appealing to investors.

Pyrolysis of Tires into Fuel Oil: Tire pyrolysis technology involves heating old tires in the absence of oxygen to decompose them into fuel oil, carbon black, steel wire, and flammable gas. Among these methods, pyrolysis recycling stands out for its significant advantages.

Common methods of recycling old tires

The Advantages of Tire Pyrolysis Recycling

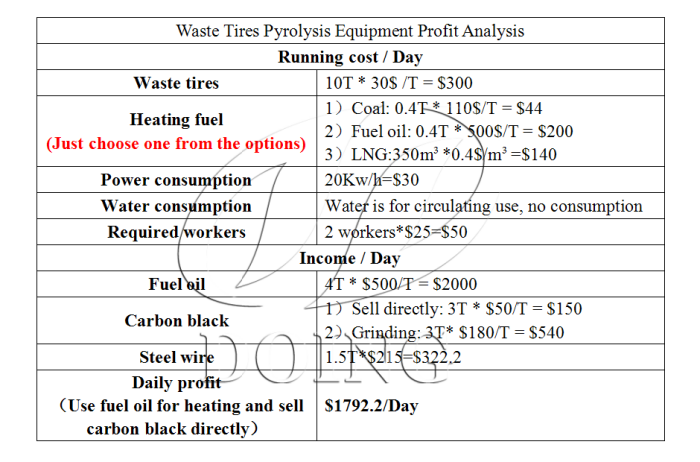

High Resource Utilization and Economic Benefits: Pyrolysis technology can convert old tires into multiple valuable products. Typically, 45% of the output is fuel oil, which can be used as heating fuel in cement plants, power plants, paper mills, and steel mills. Its calorific value is comparable to light diesel, offering a cost-effective alternative to traditional fossil fuels. Carbon black accounts for 30% of the output and can be processed further into high-value products like rubber products and inks. Steel wire, making up 15% of the output, can be sold to smelting factories. The remaining 10% is flammable gas, which can be recycled to fuel the pyrolysis process, reducing energy costs. This achieves nearly 100% resource utilization of old tires, maximizing economic benefits. Based on the profit analysis of 10TPD tire pyrolysis recycling machine, the investors may get about $1700 money out of old tires.

DOING old tire pyrolysis machine profit analysis

Additionally, in some European countries, Latin American countries and Asian countries, many cement plants, power plants, paper mills, and steel mills use fuel oil which pyrolysis from old tires as heating fuel. The effect is very good, which not only reduces production costs, but also cures the environmental problems caused by old tires.

Environmental Benefits and Policy Support: Pyrolysis recycling effectively addresses the environmental issues caused by old tires, reducing pollution and promoting sustainable development. In some European countries, governments provide subsidies for pyrolysis equipment purchases and offer priority access to recycled products in public projects. These policies not only reduce investment risks for businesses but also enhance their profitability.

DOING old tire pyrolysis machine manufacturer

In conclusion, recycling old tires, particularly through pyrolysis technology, offers significant profit potential. It not only addresses environmental pollution issues but also generates considerable economic returns. Companies like DOING are committed to providing advanced old tire pyrolysis recycling equipment and technical support to help more clients succeed in the tire recycling industry. If you have business needs in tire pyrolysis recycling, please feel free to coe pyrolysis recycling, please feel free to contact us.