Large Scale Waste Tire Recycling Facility--Continuous Pyrolysis Machine

Industry News / Chat on line / Give me a price / Date:2025-11-27

Using pyrolysis to recycle tires is an economical, efficient, and environmentally friendly method, but small-scale pyrolysis machine often fall short for growing recycling needs. Many businesses start with small-scale pyrolysis machine to recycle waste tires to fuel oil and carbon black—either for profit or to reduce their factory's operating costs. However, small-scale waste tire pyrolysis machines face bottlenecks like low throughput, frequent downtime, and high labor costs. As waste tire volumes increase, upgrading to large-scale waste tire recycling facility--continuous pyrolysis machine becomes necessary.

DOING waste tire recycling pyrolysis machine types

DOING waste tire recycling pyrolysis machine types

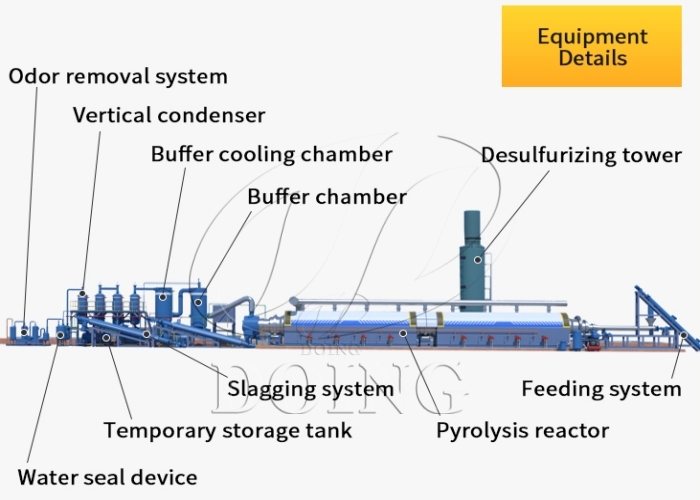

DOING has designed and developed a large scale waste tire recycling facility continuous pyrolysis machine that solves this problem through 24/7 operation, significantly improving production efficiency and reducing labor costs, making it an essential choice for facilities aiming to balance production efficiency, cost control, and resource recycling. This article will introduce DOING large scale waste tire recycling facility continuous pyrolysis machine details.

Core Features of Large Scale Waste Tire Recycling Facility--Continuous Pyrolysis Machine

For large waste tire recycling facilities, the right continuous pyrolysis machine must deliver on three critical fronts: throughput, labor costs, and stability. Below are the key features that define effective equipment:

1. Non-Stop Operation for High Throughput

The biggest advantage is its ability to run 24/7 without shutdowns for feeding or discharging. This eliminates the downtime common in small scale tire recycling pyrolysis facilities, enabling the machine to process 15/30/40/50 tons of waste tires per day—far exceeding the capacity of smaller tire pyrolysis facilities.

2. Lower Labor and Operational Costs

With its automated feeding, processing, and discharging system, this large tire pyrolysis facility reduces the need for manual intervention, lowering labor costs by 40-50% and reducing the risk of human error, thus further stabilizing production.

3. Consistent Product Quality

DOING large-scale tire pyrolysis facility employs precise PLC control to maintain stable reactor temperatures (400-600°C) and pressures, ensuring that each batch of pyrolysis oil has a uniform calorific value and consistent carbon black particle size—crucial for selling recycled products to industrial buyers.

DOING full-continuous waste tire pyrolysis machine advantages

DOING full-continuous waste tire pyrolysis machine advantages

Operation Process of Large Scale Waste Tire Recycling Facility--Continuous Pyrolysis Machine

DOING has analyzed the optimization of the large-scale waste tire recycling facility continuous pyrolysis machine process to help you fully understand how large-scale waste tire recycling facilities can leverage their advantages. The detailed steps are as follows:

1. Tire pretreatment

Waste tires are first processed to remove steel wires and crushed into 2-3cm rubber powder. This uniform feed ensures efficient heating and prevents blockages in the reactor—critical for continuous operation.

2. Feed heating

Screw-sealed feed auger to feed the rubber powder into the reactor of the large-scale tire recycling pyrolysis facility. The feeding speed of the feeder can be set to control the whole process in an orderly manner. There is a conveyor inside the reactor, and the rubber powder can complete the pyrolysis process from the front to the back and the oil gas come out.

DOING full-continuous waste tire pyrolysis machine details

DOING full-continuous waste tire pyrolysis machine details

3. Cooling

Oil gas passes through a catalytic chamber (to remove impurities) and a buffer condenser (to stabilize flow) before entering four main condensers. This multi-stage cooling process converts over 90% of oil gas into liquid fuel oil, which is stored in dedicated tanks. The pyrolysis oil can be used as fuel in brick factories, boilers, gypsum plants, and glass factories. It can be further refined into diesel fuel for heavy machinery or diesel generators.

4.Carbon Black Discharge

The carbon black produced during pyrolysis can be directly transported at high temperature via a spiral conveyor with a condenser jacket, ensuring it is discharged at near-room temperature. Carbon black can be used to make pigments or briquettes for fuel.

5.Exhaust Gas Purification

The combustible, non-condensable exhaust gas is purified by DOING environmental protection equipment into clean fuel with a high calorific value (30-40 MJ/m³) similar to natural gas, which is then transported to the pyrolysis reactor for heating. The non-combustible, non-condensable exhaust gas can be treated through DOING combustion chamber.

DOING full-continuous waste tire pyrolysis machine project case

DOING full-continuous waste tire pyrolysis machine project case

For large-scale waste tire recycling facilities, continuous pyrolysis machines are a practical solution to meet high throughput, consistent quality, and environmental goals. DOING continuous pyrolysis machine, designed with industrial-scale needs in mind, offers reliability and customization to support facilities’ long-term success. For facilities looking to scale their tire recycling operations while controlling costs, this equipment delivers on both productivity and sustainability. Welcome to contact us.