Instructions for building pyrolysis plants in Malaysia

Industry News / Chat on line / Give me a price / Date:2023-12-12

Pyrolysis plant project is very popular all over the world, which can mainly recycle tires and plastic waste into fuel oil, a kind of heating fuel used in big factories such as cement factories, glass factories and steel factories and so on. In Malaysia we have built many pyrolysis plants in various regions, like in Kuching, Penang, Klang, Johor, Ipoh, etc. For more and more customers are interested in building pyrolysis plants in Malaysia, so this passage will have an instruction for building pyrolysis plants in Malaysia:

1. Site Selection and Preparation:

Selecting an appropriate site for the pyrolysis plant is crucial. Ensure the location is conducive to industrial operations, has access to necessary utilities, and complies with zoning regulations. Adequate space for equipment installation, raw material storage, and product handling should also be considered. Take DOING 15TPD pyrolysis plant as an example, a single unit covers an area of 300 square meters, with a length of 30 meters and a width of 10 meters, so we need a place with at least 500 square meters for building this pyrolysis plant project.

DOING 15 TPD waste pyrolysis plant for sale

DOING 15 TPD waste pyrolysis plant for sale

2. Technology and Equipment Selection:

Choose reputable suppliers offering advanced pyrolysis technology and high-quality pyrolysis plants is crucial for building pyrolysis plants. Among many pyrolysis plant manufacturers, DOING won the trust and appraise of most Malaysian customers due to the excellent performance and quality of pyrolysis plant.

1)DOING pyrolysis reactor adopts the one-piece design and 3-step welding method, which can withstand high pressure and temperature to enhance work efficiency and safety; and our pyrolysis reactor can also be customized based on the raw materials you processed;

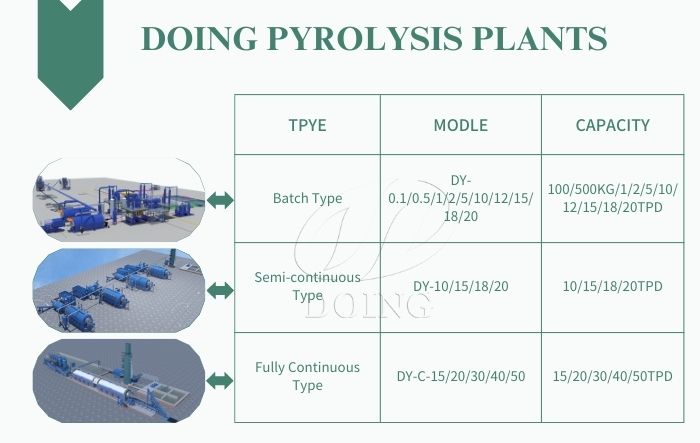

2) DOING pyrolysis plants have various types and capacities for your reference: the batch type with the capacity of 100KG to 20 tons per batch, semi-continuous type with the capacity of 10 tons to 20 tons per day, fully continuous type with the capacity of 15 tons to 50tons per day, which can meet customers' various demands.

Various types and capacities of DOING pyrolysis plants

Various types and capacities of DOING pyrolysis plants

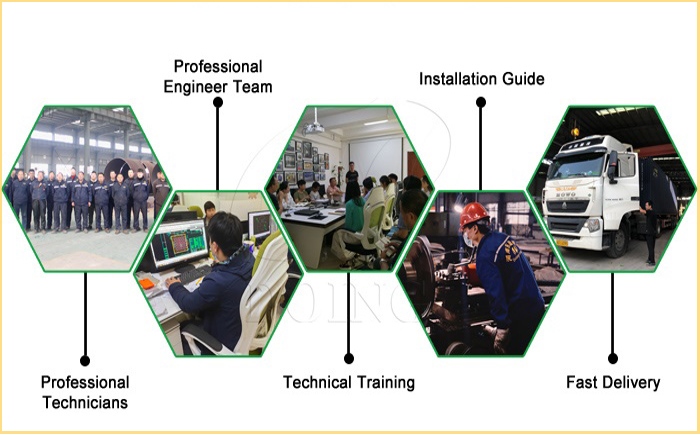

3. Installation and operational training and maintenance

Correct installation and operation method can help you build pyrolysis plants as soon as possible. When our customers receive the pyrolysis plants, DOING will arrange an engineer to provide professional guidance of installation, commissioning and training for their local workers. In addition, to ensure the successful carrying out of the pyrolysis plant, DOING also provides the one-year guarantee services to avoid unnecessary troubles for our customers.

Comprehensive services provided by DOING

Comprehensive services provided by DOING

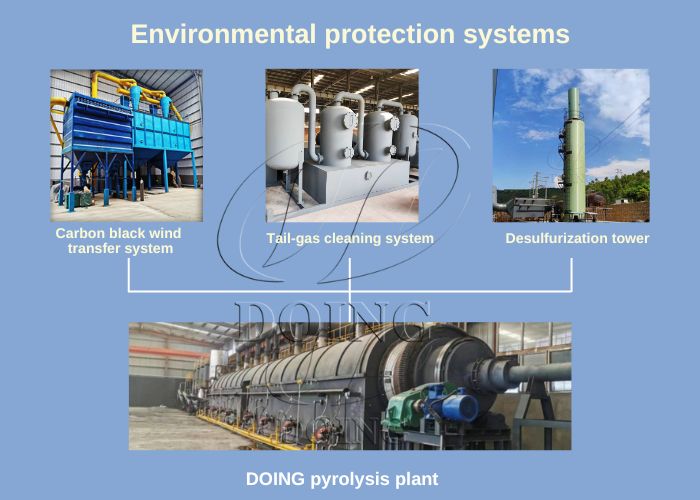

4. Environmental Impact Mitigation

To align with Malaysian sustainability goals, you need to choose the pyrolysis plant with environmental protection systems. DOING pyrolysis plant can well meet the environmental protection standards of Malaysia. We are equipped with the Tail-gas cleaning system and desulfurization tower to avoid exhaust gas pollution, and the purified gas can meet the emission standard. Our cooling system adopts circulated water, which can avoid waste water pollution. In a word, DOING pyrolysis plants can truly realize waste recycling environmentally friendly.

Environmental protection systems of DOING pyrolysis plant

Environmental protection systems of DOING pyrolysis plant

Of course, apart from the above instructions, you also need to consider other factors, such as the government policies in Malaysia, market survey of raw materials and final products, etc. If you are interested in building a pyrolysis plant in Malaysia, just feel free to contact us, our sales manager can provide comprehensive services for you based on your demands.