How much energy is required for pyrolysis plant operation?

Industry News / Chat on line / Give me a price / Date:2023-11-21

DOING's pyrolysis plant operates efficiently with low energy requirements. The energy needed for its operation includes heating fuels, electricity consumption, and water usage. Let us take a closer look at the energy requirements based on different pyrolysis plant capacities:

1. Small scale pyrolysis plant

For this type of pyrolysis plant, we have the capacity of 100KG and 500KG per day, which can be used for trial testing for various materials. Normally this type of pyrolysis plant needs about 3-5 hours per batch, you need only about 60kg oil as heating fuel, and about 3kw to 9kw electricity consumption.

DOING small scale pyrolysis plant for sale

DOING small scale pyrolysis plant for sale

2. Middle scale pyrolysis plant

For this type of pyrolysis plant, we have the capacity of 1/5/10/12/15 tons per day, and the most popular choice is the 10/12/15 TPD models. For these types, you need about 500kg oil as heating fuel and about 20kw/h electricity consumption, and the total process you consume is about 20-22 hours from feeding to final products discharging process.

DOING middle scale pyrolysis plant for sale

DOING middle scale pyrolysis plant for sale

As for the cooling water consumption, because our cooling system adopts circulated water, there is nearly no consumption for water. And apart from the small/middle scale pyrolysis plant, we also have the large scale pyrolysis plant. Of course, the energy required for pyrolysis plant operation needs more.

However, we can also obtain some final products during the operation process of the pyrolysis plant(different raw materials have different final products), which can be used as heating fuels to help you save the energy consumption for pyrolysis plant operation:

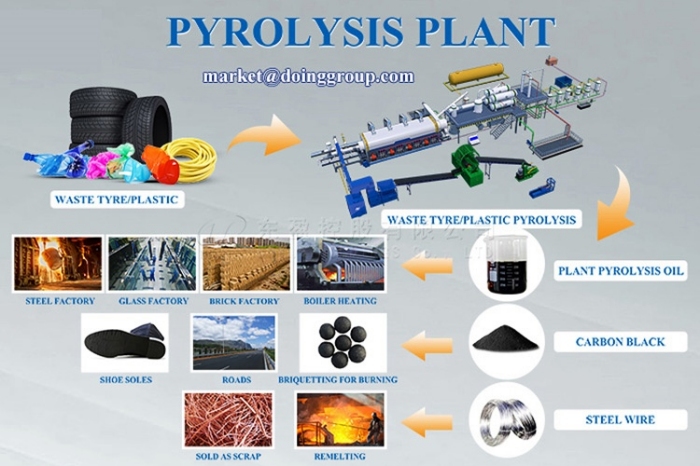

Final products and applications from pyrolysis plant

Final products and applications from pyrolysis plant

If your raw material is waste tires, you can get about 45% tire pyrolysis oil, 30% carbon black, 15% steel wire and about 10% syngas; if your raw material is waste plastic, you can get about 60% plastic pyrolysis oil, 30% carbon black and about 10% syngas.

The obtained pyrolysis oil and syn-gas both can be used as heating fuels to replace the oil fuel to save energy consumption for the pyrolysis plant operation. And the unused final products can also be sold to make more profits for our customers. The following is a brief analysis of the energy consumption and obtained profits(take the DOING 10TPD waste tire pyrolysis plant as an example):

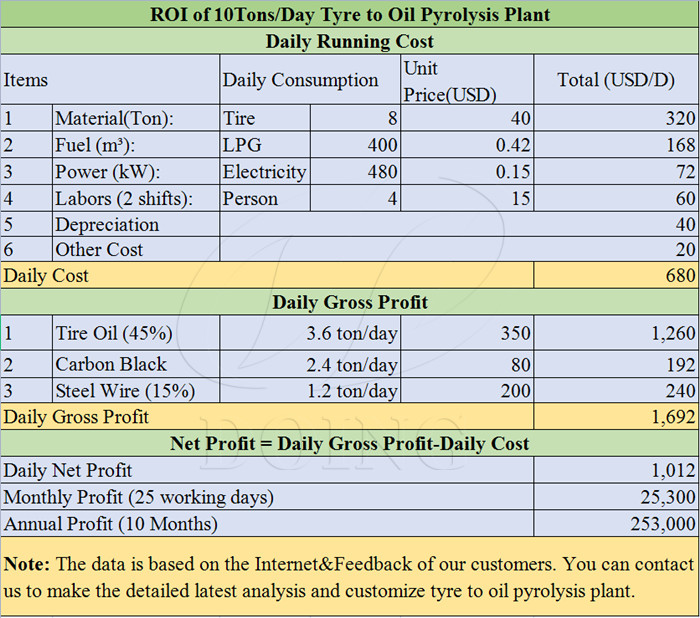

Profit analysis of DOING 10TPD waste tire pyrolysis plant

Profit analysis of DOING 10TPD waste tire pyrolysis plant

Based on market research and customer feedback, DOING's pyrolysis plants have proven to be profitable. If you start a batch pyrolysis plant project, about three months you will get back the cost and get the whole profit. So if you are interested in setting up a pyrolysis plant or want more information, please leave your inquiry. Our sales manager will provide a detailed plan based on your specific requirements.