Is pyrolysis plant capable of processing medical waste?

Industry News / Chat on line / Give me a price / Date:2023-08-03

Pyrolysis plant is capable of processing medical waste, which is a more popular medical waste treatment technology in the world in recent years.

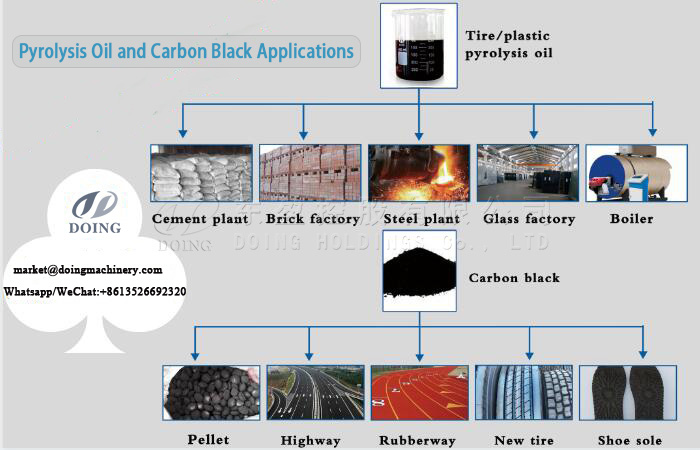

With the medical waste pyrolysis plant, we can recycle medical waste to fuel oil and carbon black, which are useful products and have wide applications:

1) Fuel oil: this fuel oil can be used as industrial heating fuels in ships, trucks, generators; further refined with waste oil distillation machine, can be used in heavy oil machinery, boilers, generators, etc.

2) Carbon black: the carbon black can be used as heating fuels and make new rubber products and paints; if it is further processed with our Grinder machine and Briquetting machine, it will have higher value and wider uses.

Multiple applications of obtained fuel oil and carbon black

Multiple applications of obtained fuel oil and carbon black

And apart from the above final products, we can also obtain other products from medical waste. For example, we can obtain the aluminum block from the waste Aluminum-plastic medicine board, etc.

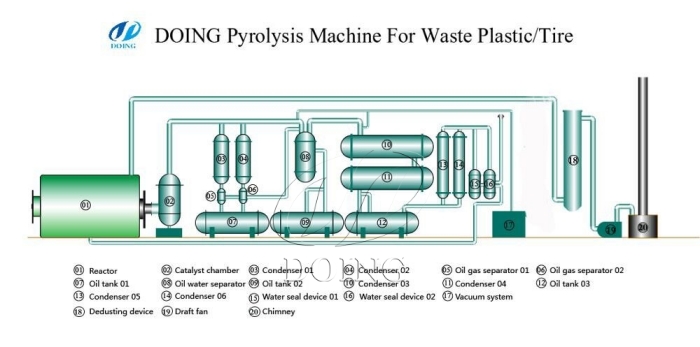

Working process:

Medical waste is recycled by pyrolysis plant through low temperature heating method (in an oxygen-free environment). The organic matter in medical waste is pyrolyzed into oil gas at a certain temperature, and it is cooled to obtain liquid fuel oil after going through the cooling system.

Working process of DOING waste pyrolysis plant

Working process of DOING waste pyrolysis plant

DOING, top manufacturer of pyrolysis plant in China, is committed to enhancing pyrolysis technology to meet customers' demands. The following are some advantages of DOING medical waste pyrolysis plant:

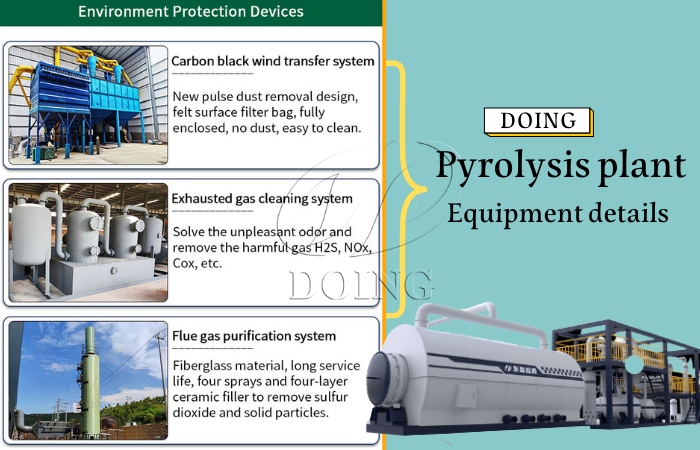

(1) Part of the non-condensing gas can be recycled to the pyrolysis reactor as heating fuel, so that the emission of solid particles is reduced to a low level, which greatly reduces the operating cost of medical waste pyrolysis plant and achieves the resource utilization of waste heat energy.

Environmental protection system of DOING pyrolysis plant

Environmental protection system of DOING pyrolysis plant

(2) DOING medical waste pyrolysis plants are equipped with some environmental protection devices, which not only harmless emissions of flue gas, reduce the total emission of CO2, but also inhibit the production of toxic and harmful objects such as dioxins under oxygen-poor conditions.

(3) DOING reactor outer insulation is fully covered to ensure the sealing and non-oxygen during pyrolysis process, which can avoid the harm to the worker and environment.

In addition, apart from the common batch type and semi-continuous medical waste pyrolysis plants, DOING also researched the fully continuous waste pyrolysis plant, which adopts the fully automatic PLC control system to have higher working efficiency.

DOING fully continuous pyrolysis plant for sale

DOING fully continuous pyrolysis plant for sale

If you are searching for an environmental method to process medical waste, please feel free to contact us, our experienced sales manager can provide guidance and advice on selecting suitable medical pyrolysis plants based on your actual demand. And our pyrolysis plant can also process other solid wastes, such as waste tires, plastics, rubbers, oil sludge, etc. Looking forward to your consulting!