Waste Plastic Pyrolysis Plant

Waste Tire/Plastic Pyrolysis Plant / Chat on line / Give me a price / Date:2020-03-26

DOING Waste Plastic Pyrolysis Plant

DOING company has been specialized in manufacturing waste plastic pyrolysis plant for more than 14+ years. We have our own professional team of engineers and are always committed to researching the latest designed pyrolysis machine to achieve faster production efficiency and the most suitable pyrolysis plant for customers. DOING company always puts machine quality and safety first. We can provide customers with the most advanced and safe waste plastic pyrolysis plant at a reasonable price.

DOING waste plastic pyrolysis plant

DOING waste plastic pyrolysis plant

Waste Plastic Pyrolysis Plant Projects

So far, we have exported to more than 90 countries and regions, including Americas, Africa, Asia, Southeast, Asian countries,such as USA, America, India, South Africa, Thailand, Vietnam, Indonesia, Fiji, Mexico, Panama, Colombia, Italy, Australia, Malaysia, Mongolia, Philippines, Chile, Nigeria, Ghana, etc., and we have some experience of local policies and markets in some countries, so can give you more accurate guidance and help.

Waste plastic pyrolysis plant partial installation projects

Waste plastic pyrolysis plant partial installation projects

There are many manufacturers of waste plastic pyrolysis plant on the market.

Why to Choose DOING Waste Plastic Pyrolysis Plant? There Are Two Main Reasons:

1. Equipment Quality, Design and Technology

Our plastic pyrolysis reactor is made of boiler steel plate, which can not only withstand high temperature but also prevent deformation. The two heads of our waste plastic pyrolysis reactor is arc-shaped design with one piece welding, instead of welding several steel plates. It enables seamless welding. Which can buffer pressure and withstand high pressure. The quality of waste plastic pyrolysis plant has been greatly improved, but at the same time the cost has also increased accordingly.

Reactor Design of DOING waste plastic pyrolysis plant

Reactor Design of DOING waste plastic pyrolysis plant

DOING waste plastic pyrolysis plant for sale adopts the full thermal insulation layer, this design can ensure that the smoke is not leaked and the heat is not lost, which not only saves fuel, but also does not cause pollution in the factory building. And our waste plastic pyrolysis plant can use the auto feeder with 1.8meters feeding door. Which can save production time and manpower. Our waste plastic pyrolysis reactor also adopt the side carbon black discharge method, the sealing effect can be achieved, it not pollute the factory, and the side carbon black discharge system is not related to the inlet and outlet. This will not affect the raw materials loading, and it will not affect the discharge of oil gas.

We have our own unique core technology, such as negative pressure system, exhaust gas purification device, etc. The negative pressure system greatly improves the safety of the entire equipment operation. The exhaust gas purification device can purify the exhaust gas and then use it to burn the reactor. This can avoid the generation of bad odor and air pollution, and also avoid complaints from people nearby. DOING waste plastic pyrolysis plant can meet different countries' environmental impact assessment standard, even America and EU standards.

DOING factory-pyrolysis plant manufacturer and supplier

DOING factory-pyrolysis plant manufacturer and supplier

2. After- Sales Installation and Maintenance

We have our own team of professional installation engineers, who can go abroad to install and debug and operate waste plastic pyrolysis plant for customers, and we have our own office and warehouse in Nigeria, which can solve problems for customers at any time. Our main markets, such as India, South America, etc. Some old customers will continue to order our waste plastic pyrolysis plant, so our engineers also install equipment in these countries all year round, which is also convenient to provide customers with after-sales service at any time.

DOING professional installation engineers

DOING professional installation engineers

Technical Parameters of Waste Plastic Pyrolysis Plant

| No. | Items | Contents | ||

| 1 | Equipmenttype | DY-1-6 | DY-1-10 | DY-1-12 |

| 2 | Rawmaterial | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structuralform | Horizontalrotation | Horizontalrotation | Horizontalrotation |

| 4 | 24-hourCapacity | 6ton | 10ton | 12ton |

| 5 | Oilyield | 2.7-3.3ton | 3.6-4.4ton | 4.5-5.5ton |

| 6 | Operatingpressure | Normal | Normal | Normal |

| 7 | MaterialofpyrolysisReactor | Q245R | Q245R | Q245R |

| 8 | ThicknessofpyrolysisReactor | 16mm | 16mm | 16mm |

| 9 | RotatespeedofpyrolysisReactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Totalpower | 19KW | 19KW | 19KW |

| 11 | Modeofcooling | Watercooling | Watercooling | Watercooling |

| 12 | Coolingareaofcondenser | 100sqm | 100sqm | 100sqm |

| 13 | Kindoftransmission | Internalgeardrive | Internalgeardrive | Internalgeardrive |

| 14 | NoisedB(A) | ≤85 | ≤85 | ≤85 |

| 15 | SizeofReactor(D×L) | 2200×6000 | 2600×6600 | 2800×6600 |

| 16 | Workingform | Intermittentoperation | Intermittentoperation | Intermittentoperation |

| 17 | Deliverytime | 20days | 20days | 20days |

| 18 | Weight | 27T | 32T | 35T |

Raw Materials Suitable for Waste Plastic Pyrolysis Plant

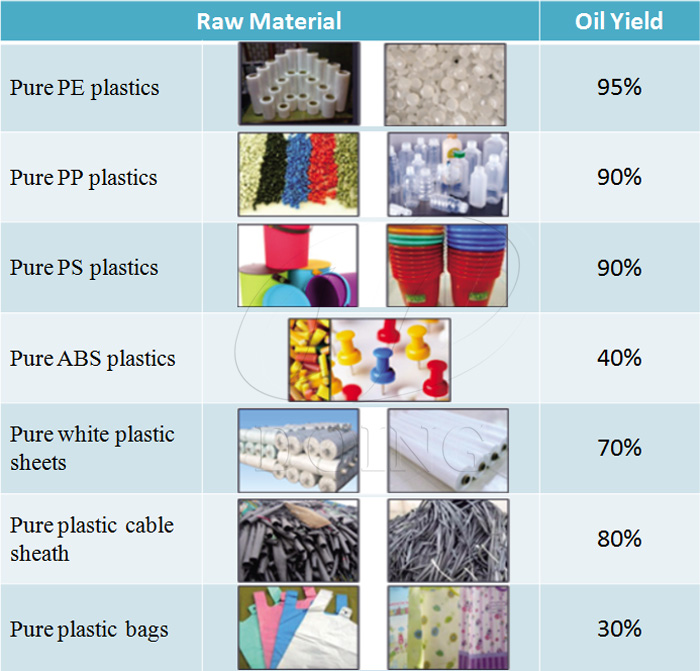

The types of plastics treated by waste plastic pyrolysis plant are limited. And different kinds of waste plastics, its oil yield is different.

For example, PE with high oil yield can reach 95%; PP and PS can reach 90%; and of course there are also some types of waste plastics that yield as little as 20% or 30%; In addition, some plastics are not suitable for oil refining, such as PVC and PET. Below are some types plastics with high oil yield.

Raw materials of waste plastic pyrolysis plant and oil yield

Raw materials of waste plastic pyrolysis plant and oil yield

Final Products from DOING Waste Plastic Pyrolysis Plant and Applications:

| Final product | Yield | Application |

| Fuel oil | 60% | 1. Be sold directly. |

| 2. Added into heavy oil generator to produce electricity. | ||

| 3. Transformed into diesel by waste oil distillation plant. | ||

| 4. As fuel to heat the pyrolysis reactor. | ||

| Carbon black | 30% | 1. Be sold directly. |

| 2. Refining as an additive in new products. | ||

| 3. Reprocessed into coal or refractory briquette. | ||

| Combustible gas | 10% | 1. Back to furnace for heating the reactor. |

| 2. Collected and sold. |

Note: here the rate of oil yield is only for reference, according to the different proportion of raw materials will be different.

Operation Process of DOING Waste Plastic Pyrolysis Plant

1. Put the dried waste plastic into the reactor by using the automatic feeder, and pay attention to leave a part of space in the reactor and not fill it completely, so that the reactor can rotate normally and the raw material can be heated evenly. Close the door of feed inlet and slag outlet after loading, and make sure the door is sealed.

2. Use one of the fuels such as coal, wood, natural gas, liquefied petroleum gas or tire oil to slowly heat the pyrolysis reactor. When the temperature reaches 160 degrees, check for oil gas coming out.

3. continuous heating, generally at 200-300 degrees, the most oil, the fastest temperature rise, need to last about 4 hours;

4. continue to heat the fire, ensure that the oil gas is felt, when the temperature drops to about 150 degrees, shut down the machine.

Production line of waste plastic pyrolysis plant

Production line of waste plastic pyrolysis plant

After the above work is completed, the reactor is cooled. Then the black carbon can be expelled automatically.

In the past decades of years, as a professional pyrolysis plant manufacturer, we DOING company insist on the quality of waste plastic pyrolysis plant first, integrity management, in the market at home and abroad to obtain a very good reputation. Repeat purchase of old customers is more common. If you are interested in in our waste plastic pyrolysis plant, please contact us in time.