Can all kinds of wastes plastic be pyrolyzed to oil?

Industry News / Chat on line / Give me a price / Date:2023-10-24

Many customers want to do waste plastic pyrolysis business, but they don't know which waste plastics can be pyrolyzed into oil. I am writing this article to answer this question for everyone.

Pyrolysis is a chemical process that high heat and pressure are applied to break down complex molecules into simpler compounds. By subjecting plastics to intense heat in the absence of oxygen, the long polymer chains are broken down into smaller hydrocarbon fragments, which can then be further refined into oil or other useful by-products.

DOING waste plastic pyrolysis to oil machine

DOING waste plastic pyrolysis to oil machine

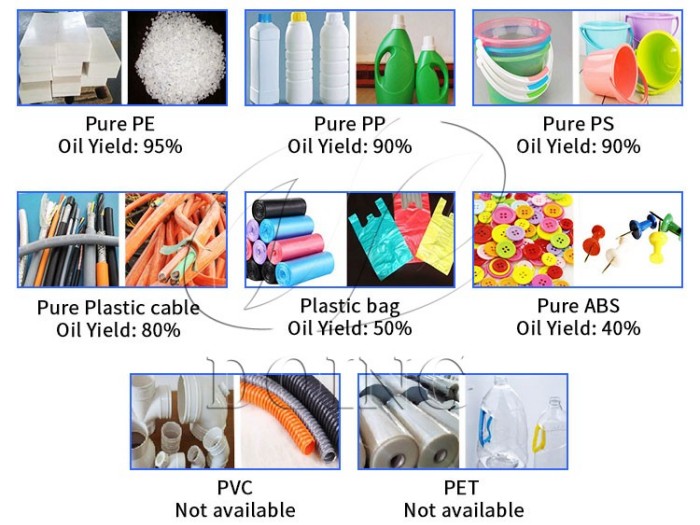

The common waste plastics types include PP, PE, PS, ABS, PET, and PVC, their suitability for pyrolysis is analyzed below.

PP, PE, and PS plastics all have high oil production rates, and the purer the plastic, the higher the oil production rate, even reaching 90-95%. The types of PE plastics also include HDPE and LDPE, which have the same properties as PE plastics and are also suitable raw materials for pyrolysis equipment.

1. Polypropylene (PP) - PP plastics, utilized in various applications such as food containers and automotive parts, have good potential for pyrolysis, yielding valuable oil products.

2. Polyethylene (PE) - PE plastics, commonly used for beverage bottles, can be converted into oil through pyrolysis. The resulting oil can be as fuel or refined into diesel oil.

▪ High-Density Polyethylene (HDPE) - HDPE plastics, commonly found in milk jugs and detergent bottles.

▪ Low-Density Polyethylene (LDPE) - LDPE plastics, including plastic bags and packaging films.

They are suitable for pyrolysis and can be pyrolyzed into oil or other valuable products.

The oil yield of different waste plastic types

The oil yield of different waste plastic types

3. Polystyrene (PS) - PS, commonly known as Styrofoam, commonly found in disposable tableware and lunch boxes, which has high oil yield as PP and PE.

4. Acrylonitrile Butadiene Styrene(ABS) - ABS waste plastic is also commonly used for pyrolyzed into oil, and the oil yield of pure ABS plastic can reach 40%. For plastics, this level of oil yield is considerable.

However, PVC and PET are not suitable for pyrolysis to oil.

5. Polyvinyl Chloride (PVC) - PVC is the most common and basic plastic which only contains carbon and water molecules, often used in pipes and vinyl flooring. During the pyrolysis process of PVC, it shall generate HCL, which is a toxic gas and at the same time acid gas causes great corrosion to the equipment. Therefore, it is not a preferred plastic for this recycling method.

6. Polyethylene Terephthalate (PET) - PET plastics, commonly used for beverage bottles, which belong to Thermoplastic polyester, or saturated polyester, during the high temperature cracking there is very little chance to become olefins, almost no. That's why this kind of plastic has no oil.

The waste plastics can be pyrolyzed to oil

The waste plastics can be pyrolyzed to oil

The recycling channels for the above PP/PE/ PS/ABS waste plastics are easy to find. And if your waste plastic raw material is mixed, it is still ok for pyrolysis. Therefore, for entrepreneurs and investors who want to do plastic pyrolysis oil business, these types of plastics can be their choices.

This is Henan Dong Group, a Chinese supplier specializing in the manufacturing of waste recycling and environmental protection equipment such as waste tires/plastic pyrolysis to oil machines and waste oil distillation machines. If you are not sure whether your waste plastic can be pyrolyzed to oil, you can consult us. Or if you are interested in our waste plastic pyrolysis to oil machine, please leave us a message.