Waste oil distillation plant for sale-Convert waste oil to Diesel

Waste Oil Refining Machine / Chat on line / Give me a price / Date:2019-01-21

In order to realize the economic and environmental benefits of waste oil, DOING company developed and produced waste oil distillation plant by using distillation technology. Waste oil distillation plant is specially designed for waste oil, crude oil and pyrolysis oil, which can distill black and heavy waste oil and pyrolysis oil into clean and bright diesel. Diesel can be used in diesel burners, generators and heavy machinery, etc. Below I will introduce the waste oil distillation plant.

Waste oil distillation plant

Waste oil distillation plant

The unique advantages of DIONG's waste oil distillation plant:

1. High safety coefficient

The process of waste oil distillation plant is carried out under normal temperature and pressure, which is relatively safe;

2. High conversion rate

The unique catalyst can make the conversion rate of waste oil to diesel reach over 90%.

3. Cost saving

The non-condensable gas produced in the heating process can flow directly into the reactor for fuel combustion. This saves fuel costs

4. With strong variability

DOING‘s waste oil distillation plant has a lot of operation space in the design, the same equipment, different operation procedures, will produce different oil, customers can according to their own requirements for oil to operate.

Environmental protection of waste oil distillation plant:

1. Exhaust purification treatment standards

The soot emitted by fuel combustion will be treated by tail gas treatment so as to emit a small amount of white smoke. White smoke is mainly composed of water vapor and carbon dioxide. The dust removal rate of tail gas treatment system can reach above 95%, which can fully meet the national emission standard.

2. Waste gas recovery

Non-condensable but flammable gas produced during distillation process at elevated temperatures. Through the water seal collection system, we deliver these gases to the reactor for full combustion, which is both environmentally friendly and energy saving.

3. Wastewater discharge is almost zero

With the circulating water cooling system, water emissions are almost zero.

DOING waste oil distillation plant for sale

DOING waste oil distillation plant for sale

Solid catalyst distillation working process of waste oil distillation plant:

First, the heat conduction oil is heated by the heat conduction oil furnace, and then the heat conduction oil flows into the coil pipe which is inside the distillation reactor, and the waste oil is heated in the reactor. Using this heating method can better control the temperature and is conducive to the following operation.

Second, as the temperature increases, the waste oil produces oil gas and flows into the buffer tank. There are fillers in the buffer tank, which can purify the oil gas, control the oil gas emission rate, and prevent the oil from the distillation reactor from entering the catalytic tower and causing the solid catalyst of the catalytic tower to fail. When the oil gas pass through the buffer tank and the temperature is controlled, the light components in the waste oil can be distilled and collected into the distillate tank. Light oils often contain a strong smell, also known as the odor fraction. The odor fraction is collected and a better oil is obtained.

Third, with the further increase of temperature, oil gas from the distillation reactor into the catalytic tower, in the catalytic tower there are two kinds of catalysts: catalyst A for absorption, catalyst B for cracking. Through the catalytic tower, the oil gas are split into small molecules of oil, and out of the deep color.

Forth, after passing through the catalytic tower, small molecules of oil gas are cooled into liquid oil through the cooling system and collected into the oil tank.

Fifth, after all the oil gas is evaporated, the remaining in the reactor is hot asphalt, which can be directly pumped out by the asphalt pump.

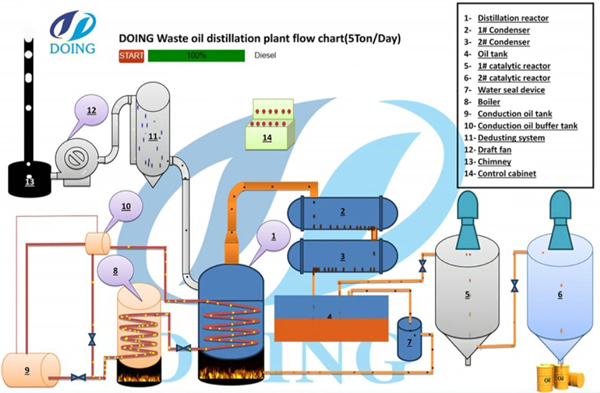

Waste oil distillation plant flow chart

Waste oil distillation plant flow chart

Finally, I will make a simple profit analysis for DOING's waste oil distillation plant.

Profit analysis:

Through this process, we can get 85-90% of diesel and 10-15% of bitumen. We will use the following input and output to conduct a profit analysis.

Operating costs

Waste oil: 10 T X288 USD/T = 2880USD

Heating the fuel can use any of the following:

1) Coal: 0.4 T X 64 dollars/T = 25 dollars

2) Fuel: 0.6 T x 478 dollars/T = 287 dollars

3) Diesel: 0.5 T X 765USD/T = 382 dollars

4) Natural gas: 200m3 X 0.36USD / m3 = 72USD

Power consumption: 25KW / h X O.16USD X 20h = 80h

Water consumption: water reuse, almost no consumption

Workers: 1-2 people X 16USD = 32 dollars

Earnings/day

Fuel: 8 T X 765 dollars/T = 6118 dollars

Asphalt: 1.5 T X 175USD/T= 263 dollars

Profit/day (calculated on fuel diesel) $3017.