DOING Pyrolysis Plants Video: Waste Plastic & Rubber Tyre Processing

Video / Chat on line / Give me a price / Date:2025-02-26

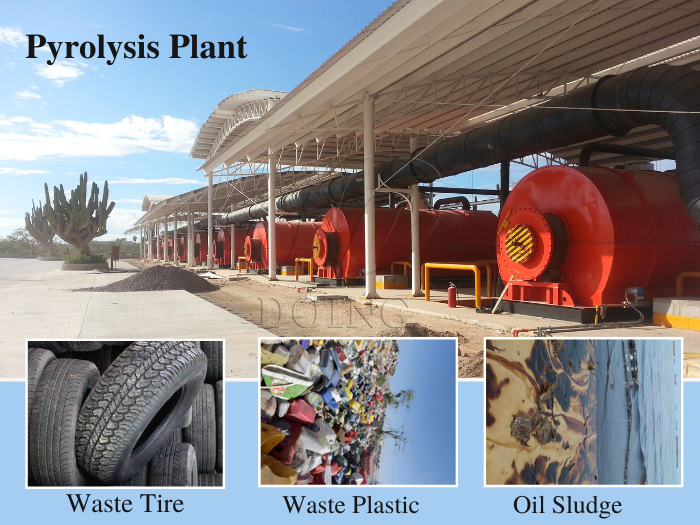

Welcome to a look at our versatile 15TPD Pyrolysis Machines processing both waste plastic and rubber. These 6 sets of pyrolysis is engineered for adaptability, allowing waste management and recycling companies to maximize their resource recovery. Whether you're dealing with mixed plastic streams or end-of-life tires, our technology offers a powerful solution for converting waste into valuable commodities like fuel oil and carbon black.

This equipment is ideal for businesses seeking to diversify their feedstock handling. It can process more than 30,000 tons of waste rubber tyre and plastic scrap. However, it's crucial to note that waste plastic and rubber materials should be processed separately. While both are valuable feedstocks, their distinct chemical compositions and processing requirements necessitate individual runs for optimal efficiency and product purity. Processing them simultaneously can lead to compromised output quality and potential equipment strain.

Waste plastic and rubber tyre pyrolysis plant

Waste plastic and rubber tyre pyrolysis plant

Watch now to witness the efficient operation and understand how our dual-capable pyrolysis machines can enhance waste to energy resource processing capabilities. Henan Doing Company looks forward to working with you to help you customize the right pyrolysis plant solution and help you successfully implement an environmentally friendly and profitable waste recycling and reuse project!