How to make crude oil from waste plastic?

FAQ / Chat on line / Give me a price / Date:2022-09-22

Many countries are studying how to deal with plastic wastes and recycle them into crude oil in an environmentally friendly way. There is a new idea and technology------Plastic pyrolysis, which could convert the waste plastic into crude oil through the waste plastic pyrolysis plant produced by Henan DOING GROUP.

Batch type waste plastic pyrolysis plant

Batch type waste plastic pyrolysis plant

DOING Plastic pyrolysis plant is mainly including 3 parts, which are pyrolysis reactor heating system, oil gas cooling system and flue gas purification system. The whole pyrolysis system will make these waste plastics fully pyrolized into crude oil with a high oil yield. General the waste plastic to crude oil production processes are as below:

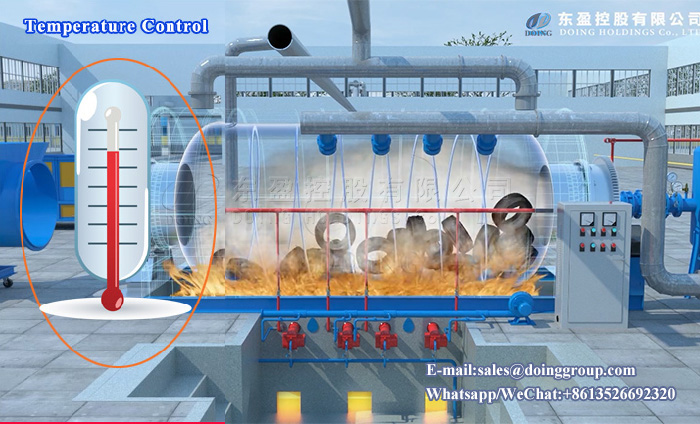

1. Pyrolysis reactor heating process

Put waste plastic into the pyrolysis reactor through the feeding door. At the beginning, the pyrolysis reactor needs to be heated for approximately 2 hours for preheating. DOING plastic pyrolysis plant can be heated by fuel oil, gas, wood, coal etc.

P.s.Some flue gas will be recycled to heat the reactor once the oil gas starts to come out and there is no need to use the extra material to heat the pyrolysis reactor, which saves much cost of heating.

Pyrolysis reactor heating process

Pyrolysis reactor heating process

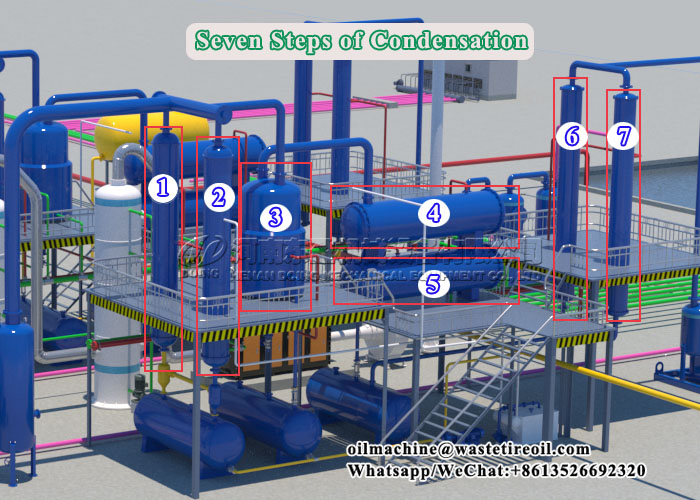

2. Oil gas cooling process

The generated oil will enter the cooling system and condensed into liquid crude oil. The oil gas cooling system of DOING plastic pyrolysis plant includes two sets of vertical condensers and 2 sets of horizontal condensers, which is the most professional cooling system of industries. Besides that, there is a set of oil-water separators and two sets of cooling towers which definitely will get all the oil gas to be cooled down during production to improve the oil yield.

Oil gas cooling process

Oil gas cooling process

3. Flue gas purification process

Then the flue gas generated in the waste plastic to crude oil production process will be purified by the environmental protection device, flue gas purification system. It can filter the dust and remove some little sulfide which is contained in the flue gas. DOING plastic pyrolysis plant can make sure that the emission is friendly to the environment and meet the policy requirements of each country.

After these processes, you could obtain the crude oil from waste plastic. With mature pyrolysis technology and good performance, DOING's pyrolysis plants have been popular sale in 90+ countries and well recognized by our clients. For more details about our waste plastic pyrolysis plant, please feel free to contact us for more information.