How Much is One Ton of Waste Plastic? Unlock Profit in Waste Plastic With Pyrolysis Machine

Industry News / Chat on line / Give me a price / Date:2025-10-21

A common question from businesses and municipalities grappling with plastic waste is: How much does one ton of waste plastic cost? The answer is complex, varying widely by plastic type (PET, PE, PP, PS), contamination level, and regional market conditions. In many regions, mixed or contaminated plastic waste can have a low or even negative value, with disposal costs ranging from $20 to $100 per ton.

However, this acquisition cost is merely the starting point of a highly lucrative value chain, centered on plastic pyrolysis machine. Waste plastic, once considered a problematic environmental burden, is now emerging as a valuable commodity in the global market. Investing in this conversion process is becoming increasingly profitable.

Waste plastic recycling pyrolysis products

Waste plastic recycling pyrolysis products

1. High Value Addition and Profit Margins

The core of profitability lies in value addition. Pyrolysis machines thermally convert waste plastic into valuable fuel oil, carbon black, and syngas. While a ton of mixed plastic waste might cost you $30-50 to manage, the pyrolysis products derived from it can command a significantly higher price. The primary output, plastic pyrolysis oil, can sell for approximately $400 to $650 per ton, depending on quality and market. This transformation process turns a liability into a portfolio of sellable commodities, unlocking substantial profit margins by bridging the gap between low waste cost and high energy/product value.

2. Strong and Diversified Market Demand

The demand for the outputs of plastic pyrolysis process is robust and growing globally. These products are essential in various industries:

Pyrolysis Oil: Serves as an alternative industrial fuel for boilers, furnaces, and heavy oil power generators. It can also be further refined through pyrolysis oil refinery plant into diesel for treactors, trucks, ships, heavy machinery, etc.

Waste plastic pyrolysis products applications

Waste plastic pyrolysis products applications

Carbon Black: Used as a reinforcing agent in rubber products (e.g., tires, hoses), as a pigment in plastics, and in the production of inks.

Syngas: Often recycled to heat the pyrolysis reactor itself, significantly reducing external energy costs and increasing overall efficiency.

This diverse demands of waste plastic recycling pyrolysis products create multiple revenue streams from a single feedstock, ensuring a ready market for the end-products.

3. Addressing Environmental Regulations and ESG Goals

Globally, regulations on plastic waste disposal are tightening, with bans on landfills and increased emphasis on circular economy principles. Investing in a pyrolysis plant is not just a financial decision but a strategic one. It demonstrates a commitment to Environmental, Social, and Governance (ESG) goals, turning a waste management problem into a sustainable resource recovery operation.

4. Government Incentives and Circular Economy Potential

Many governments and local authorities are now offering incentives, including tax benefits, grants, and green certifications, to support recycling and waste-to-energy projects. This support improves the return on investment. Furthermore, by producing fuel and raw materials locally, pyrolysis plants contribute to regional energy security and reduce dependence on virgin fossil resources, positioning your operation at the forefront of the circular economy.

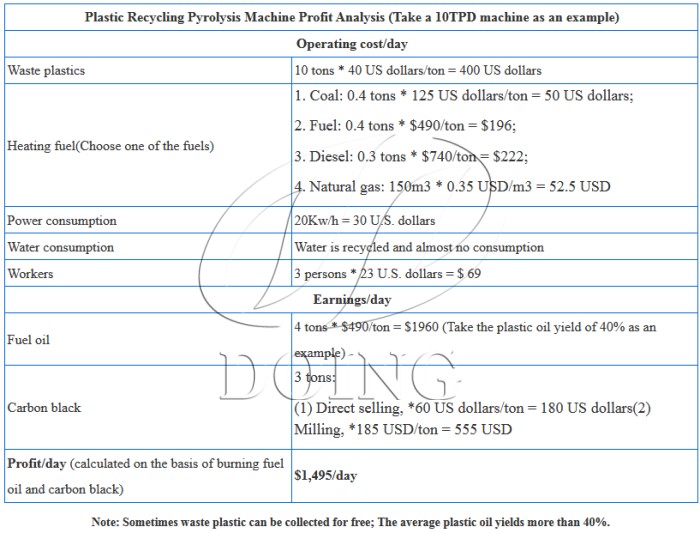

10 ton waste plastic recycling pyrolysis machine profit analysis

10 ton waste plastic recycling pyrolysis machine profit analysis

While the cost to acquire or manage a ton of waste plastic may be low, the real financial and environmental opportunity lies in its advanced conversion. The waste plastic pyrolysis business is profitable due to the significant value addition from turning waste into in-demand commodities, strong and diversified market demand, alignment with global sustainability trends, and potential regulatory support. For entrepreneurs, waste managers, and industrial companies seeking a sustainable venture with tangible returns, investing in plastic pyrolysis technology represents a strategic and rewarding opportunity.

Note for Our Readers:

Please note that as a manufacturer of waste plastic recycling pyrolysis machines, we Henan Doing Company supply various scales of pyrolysis machines and solutions. We do not purchase waste plastic. If you are looking to sell your plastic waste, we recommend exploring the following channels:

Local recycling centers and scrap yards.

Online waste trading platforms and B2B marketplaces.

Industrial companies that use pyrolysis plants (like cement plants, power plants).

Waste management and brokerage firms specializing in plastic streams.