PP Polypropylene Plastic Waste Pyrolysis: Recycling Process, Product Characteristics, and Investment Prospect Analysis

Industry News / Chat on line / Give me a price / Date:2025-12-09

Currently, effectively treating and recycling waste plastics at high value has become an urgent environmental and economic challenge. Polypropylene (PP), as the second largest general-purpose plastic in terms of production volume after polyethylene (PE), has a significant environmental burden due to the proliferation of its waste. However, with the help of advanced pyrolysis technology, these PP plastic wastes, considered useless garbage, are having an opportunity for reuse and being transformed into valuable resources.

As a professional manufacturer of pyrolysis equipment, Henan Doing Company is committed to promoting the innovation and application of PP Polypropylene plastic waste pyrolysis technology, revealing its enormous potential.

I. Which PP plastic wastes are suitable for pyrolysis?

The core of PP plastic waste pyrolysis is to use pyrolysis equipment to heat waste plastics in an anaerobic environment, breaking down their molecular structure and converting them into oil, gas, and solid residue. This process not only reduces the environmental impact of PP plastic waste but also achieves resource reuse. Efficient and economical pyrolysis requires preliminary screening of raw materials.

Polypropylene plastic waste feedstocks for recycling pyrolysis plant

Polypropylene plastic waste feedstocks for recycling pyrolysis plant

Polypropylene plastic waste is one of the most common plastic wastes, widely used in packaging, home appliances, automotive parts, and many other fields. Among them, the following types of PP plastic waste have high pyrolysis value:

Please mixtures with uniform composition: For example, pure PP scraps, substandard or recycled materials from automotive interior parts, appliance casings, packaging films (such as food packaging and industrial stretch film), PP hollow boards, and plastic billboards. These materials have relatively simple compositions, making the pyrolysis process easy to control.

Cleaned PP packaging containers: Such as PP plastic bags, yogurt cups, takeout boxes, and beverage bottle caps, which can also be effectively pyrolyzed after simple cleaning to remove residues.

Waste PP fibers and fabrics: Carpets, non-woven fabrics, clothing, etc., if the main component is PP and the impurity content is not high, are feasible pyrolysis raw materials.

Some Polypropylene composite materials (requiring special treatment): For example, PP products containing small amounts of other polymers or fillers can be processed under specific pyrolysis conditions.

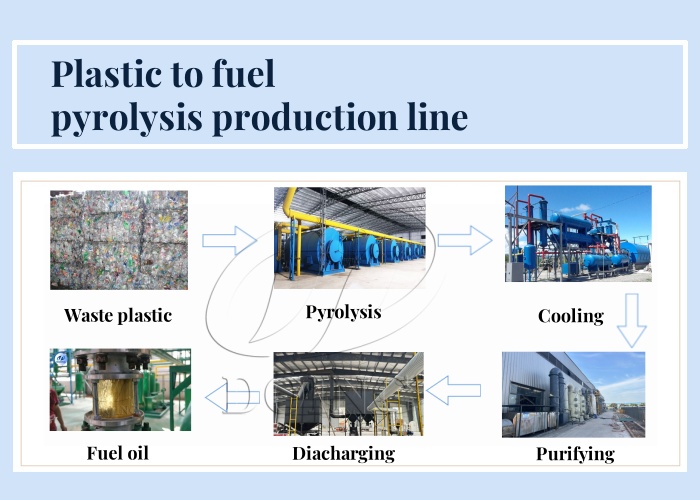

II. Pyrolysis Process Flow of PP Polypropylene Plastic Waste

DOING's rotary plastic pyrolysis plant, with its advantages of high-efficiency heat transfer, uniform heating, diverse processing capacity, and stable operation, has become an ideal choice for PP plastic pyrolysis. This provides an efficient and stable solution for the recycling and treatment of PP plastic waste. The core process flow is as follows:

PP polypropylene plastic pyrolysis process

PP polypropylene plastic pyrolysis process

Step 1. Raw Material Pretreatment: (Optional, generally for fully continuous plastic pyrolysis technology): Collection, sorting, washing (removing contaminants and moisture), and crushing (to a suitable size, typically 10-30mm) are the crucial first steps to ensure the purity and uniformity of the raw materials.

Step 2. Feeding: DOING typically equips the feeder with devices such as hydraulic feeders and screw conveyors, based on the customer's budget and automation requirements, to uniformly and stably feed the pretreated Polypropylene plastic waste into the pyrolysis reactor.

Step 3. Pyrolysis Reaction: Under anaerobic or oxygen-deficient conditions, PP plastic waste undergoes molecular chain breakage at high temperatures, decomposing into small molecule gases and oil-gas mixtures. For PP plastic, the optimal pyrolysis temperature is typically controlled between 300°C and 550°C.

Polypropylene plastic pyrolysis reactor

Polypropylene plastic pyrolysis reactor

Step 4. Oil-Gas Condensation and Separation: The oil-gas produced by pyrolysis is cooled and condensed into liquid pyrolysis oil based on its boiling point, and the non-condensable pyrolysis gas is further separated.

Step 5. Oil-Gas Condensation and Separation: Pyrolysis Gas Recovery and Utilization: Non-condensable pyrolysis gases (mainly hydrogen, methane, ethylene, etc.) are rich in energy and can be used to provide heat for the pyrolysis equipment itself, achieving energy self-sufficiency and reducing operating costs.

Step 6. Residue Treatment: Pyrolysis mainly produces carbon black (a high-value byproduct) and a small amount of non-pyrolyzable inorganic matter. The carbon black, after collection and further processing, can be used in the rubber, ink, and coating industries.

Step 7. Flue GasTreatment: DOING plastic pyrolysis plant is equipped with multi-stage environmental protection equipment to treat the flue gas generated during the pyrolysis process, ensuring compliant emissions.

Environmental pp plastic pyrolysis system

Environmental pp plastic pyrolysis system

III. PP Plastic Pyrolysis Products: Characteristics and Yield of Regenerated Oil

The main product of Polypropylene plastic pyrolysis is recycled oil (also known as pyrolysis oil), with a product yield as high as 75%-85%, meaning that approximately 750-850 kg of pyrolysis oil can be extracted from 1 ton of waste PP plastic.

The recycled oil obtained from the pyrolysis of PP plastic contains various small-molecule organic compounds such as alkanes, olefins, and aromatics. It has a high calorific value and low sulfur content, resulting in excellent environmental performance.

PP plastic pyrolysis oil has wide-ranging applications: It can be used as fuel for industrial boilers and heating equipment in industries such as steel mills, galvanizing plants, brick factories, cement plants, and heavy oil power plants, replacing some fossil fuels and reducing energy costs. It can also be fractionated through distillation and refining processes to produce diesel-like oil products for use in heavy machinery, ships, boats, diesel generators, trucks, etc.

IV. Feasibility of Investing in PP Plastic Waste Pyrolysis Projects

Investing in PP Polypropylene plastic waste pyrolysis plant projects is not only a demonstration of environmental responsibility but also a strategic choice to seize the opportunities of green economic development. The project's feasibility and profitability are mainly reflected in the following aspects:

Low or even negative raw material costs: Waste PP Polypropylene plastic is widely available as a raw material, with extremely low acquisition costs. In some regions, there is even a "paid purchase" model, resulting in low raw material harvesting costs.

High added value of products:

Recycled Pyrolysis oil: As an energy product that can replace fossil fuels, or be further refined into chemical raw materials, it has stable market demand and a considerable selling price.

Carbon black: As a high-value-added industrial raw material, it is widely used in tires, rubber products, pigments, and other fields, with stable market demand.

Pyrolysis gas: Achieves energy self-sufficiency, saving a significant amount of cost from purchased energy.

Strong policy support: Governments in various countries provide varying degrees of policy support for the environmental protection industry, the circular economy, and new energy fields, including subsidies and tax incentives, providing a favorable external environment for project operation.

Significant environmental benefits: Properly handling waste plastics reduces environmental pollution from landfills and incineration, helping to gain wider market acceptance.

High technological maturity and stable operation: Polypropylene plastic pyrolysis technology has matured after years of development, with stable and reliable equipment operation, and ease of operation and maintenance.

PP plastic pyrolysis plant manufacturer services

PP plastic pyrolysis plant manufacturer services

Polypropylene Plastic waste pyrolysis projects offer a considerable return on investment and a stable profit cycle. If you are considering investing in a PP plastic recycling pyrolysis business, please contact Henan Doing Company for a comprehensive solution, from project consultation and equipment selection to process design, installation and commissioning, worker training, and operation guidance.