What's the waste plastic pyrolysis process, how does pyrolysis technology work?

FAQ / Chat on line / Give me a price / Date:2018-11-13

As the waste plastic amount is generated higher and higher, the waste plastic pollution is also becoming heavier and heavier. So, it’s very urgent and important for the world to find a way how to dispose the waste plastics , thus to prevent or reduce the pollution caused by waste plastics.

Waste plastics

Waste plastics

What’s plastic pyrolysis process?

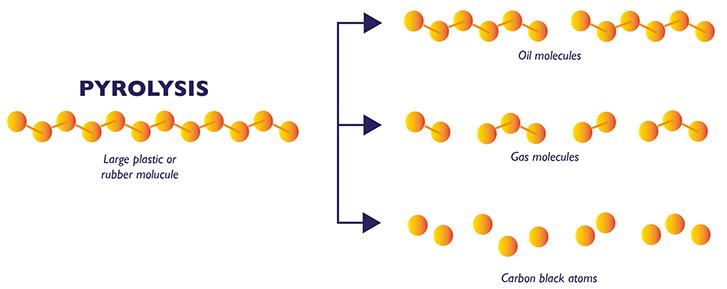

Waste plastic pyrolysis means the process that under a sealed furnace with proper heating, the main chain in plastics cracked into monomer, biopolymer and fragments, which then be polymerized to many kinds of olefins, thus get rid of the volatile substances to solid carbon. The main end products are fuel oil, pyrolysis gas and carbon black. The composition of every product is different as different pyrolysis methods, temperature, etc.

Waste plastic pyrolysis process

Waste plastic pyrolysis process

Through plastic pyrolysis process, it could recycle waste plastics to renewable energy, also without generating secondary pollution to the environment. And DONG Company’s new type waste plastic pyrolysis plants are all equipped with smoke cleaning system, tail gas cleaning system, bad smell removal system and water circulation system, thus to keep no pollution to both the air and water.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

How does pyrolysis work?

The formula of the pyrolysis process is as below:

(-CH2-CH2-)n → n[C+H2+CH4+C2H6+C3H8+C4H10+…+C11H24+…C20H42+…]

(Remark: C5H12~C11H24 is gasoline fraction, C12H26~C20H42 is diesel fraction, C20 above is heavy oil fraction).

Plastic pyrolysis technology

Plastic pyrolysis technology

Normally, the operation temperature of the waste plastic pyrolysis process is about 200-450℃. DOING’s pyrolysis reactor adopts heating from outside with sealed design, thus to keep no gas leak out, not only increase the pyrolysis efficiency, but also eliminate the potential risk of safety problem and pollution.