What is the best way to recycle waste plastic?

FAQ / Chat on line / Give me a price / Date:2018-08-13

Waste plastic buried

Waste plastic buried

Waste plastics are usually buried and not easily degraded, and it generate big pollution when it is burned. Only recycling is the best solution. In the face of obstacles such as cost, technology, and utilization value that have been on the road to the development of waste plastics recycling industry, the space for internal consumption has expanded, and the innovation of processes and equipment has accelerated. The potential of the entire market cannot be underestimated.

The danger of discarding plastic products at random is presumably familiar to many people. In recent years, the issue of how to dispose of waste plastics is also on the hot list. Conventionally, the main treatment methods for waste plastics are landfill, incineration, and recycling. For landfill, the plastic itself is not an easily degradable product; And for incineration, the heat generated by the large amount of exhaust gas, even in the incinerator is also likely to cause damage to the furnace.

Waste plastic landfill

Waste plastic landfill

This shows that the recycling method is more environmentally friendly. However, the recycling and reuse of plastics on the one hand have manpower and material costs, on the other hand, the reuse channels are still occluded, and the reuse value is suppressed. Therefore, for a long time, recycling of waste plastics has been advocating, but it has also avoided the ruin of business.

Of course, this is the past, and now the waste plastic recycling industry has been completely renewed. First of all, all countries in the world, including China, are investing in manpower, material resources, financial resources, innovating key technologies, optimizing management models, focusing on reducing costs and promoting the recycling and reuse of waste plastics. So far, thermal energy recovery, physical recovery, chemical reduction, hydrogenation and other methods have entered in the industry.

In the past, the domestic waste plastics market was not good, and part of the reason was also attributed to the huge scale of waste plastics imports, which blocked quite a lot of market demand. Nowadays, the import ban on waste plastics has been released, and the domestic waste plastics industry will be re-arranged. This also means that domestic demand will gradually shift to internal consumption, and more businesses will choose to tap the recycling potential of domestic waste plastics.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

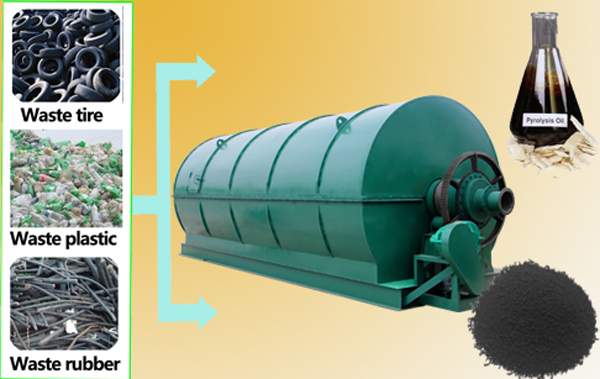

Now DOING company has developed waste plastic pyrolysis plant, which can recycle waste plastics without any environmental pollution. Its main working principle is to use pyrolysis chemical reaction to crack waste plastic into oil and gas in a closed, anaerobic and high temperature environment, and further cool to obtain fuel oil, carbon black, and combustible gas.

These substances have a very important role in our lives. The specific uses are as follows:

Fuel oil application

Fuel oil application

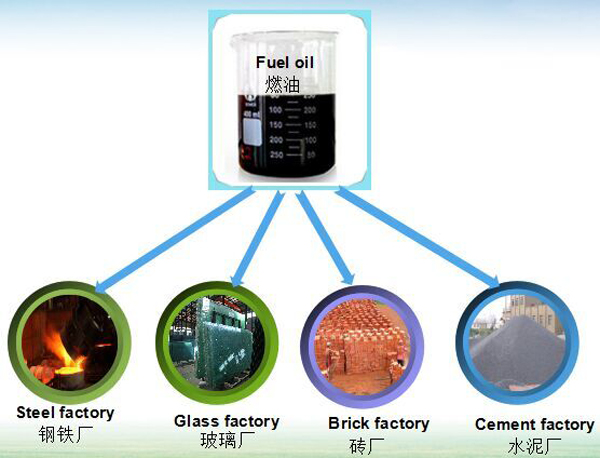

1. Fuel oil: it can be widely used in marine boiler fuel, furnace fuel, metallurgical furnace and other industrial furnace fuels. Depending on the application, fuel oil can be classified into marine fuel oil and furnace fuel oil and other fuel oils. According to the statistics of the National Bureau of Statistics, China's fuel oil consumption is mainly concentrated in power generation, transportation, metallurgy, chemical, light industry and other industries.

Carbon black application

Carbon black application

2. Carbon black: It is mainly used for briquetting for burning and refining . Among them, refined powder can be used for the manufacture of new tires, rubber soles and pigments.

3. Combustible gas: It will be recycled by the equipment. Reheating the fuel used in the reactor is energy efficient and environmentally friendly.

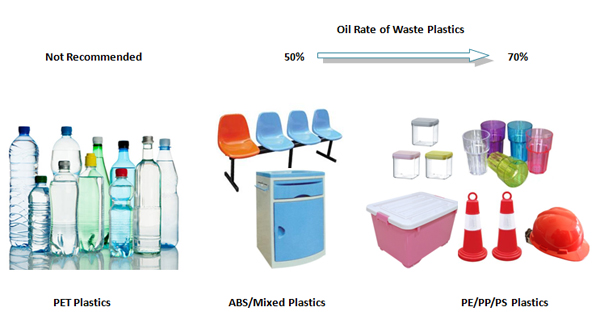

Many customers have feedback to us that they mainly use waste plastics pyrolysis plant to obtain fuel oil. The main concern is the oil yield of waste plastics. For the oil yield of waste plastics, it is also the kind of waste that customers use. Plastics are used as raw materials. The oil yield of different waste plastics is also different, and specific analysis is needed. In order to meet the most concerned issues of our customers, based on our many years of industry experience, we have summarized the following oil yield of waste plastic pyrolysis plant for your reference:

Different kinds waste plastic oil yield

Different kinds waste plastic oil yield

From these data, we calculate the oil yield of waste plastics by the average value of 50%. From a set of 10 tons of waste plastics pyrolysis plant , we can get 5 tons of fuel in one day. Now the price of one ton of fuel oil on the market is 3200RMB, which means that from 5 tons of fuel oil, we can get the benefit of 16000RMB. This is just the profit we can get on one day of equipment operation, and this profit does not include another part of the material carbon black that can bring us profits!

DOING company waste plastic pyrolysis plant

DOING company waste plastic pyrolysis plant

Our waste plastic pyrolysis plant not only protects the environment, but also can bring you a steady stream of benefits! This is the significance of our waste plastics pyrolysis plant and one of the most cost-effective ways to recycle waste plastics.