What are the options for waste tire/plastic pyrolysis recycling machines?

FAQ / Chat on line / Give me a price / Date:2022-04-09

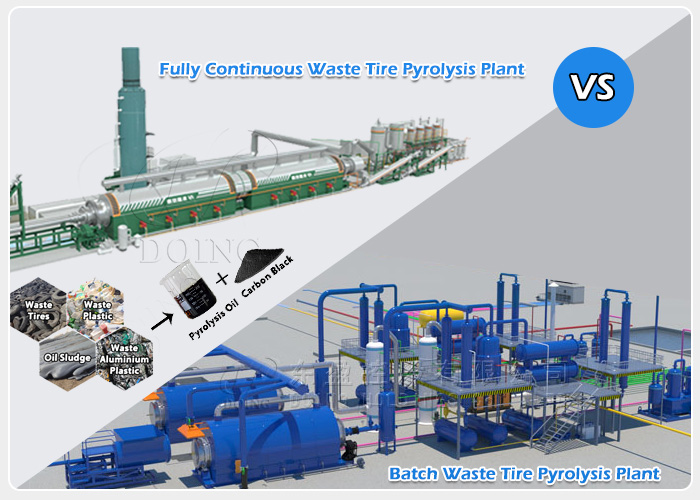

Now the waste tire/plastic pyrolysis project is very popular in the world, and more and more people want to seize the chance to engage in the pyrolysis plant project to make great money. And for new investors, there are mainly two options for waste tire/plastic pyrolysis recycling machines, one is the continuous type pyrolysis recycling machine, and the other is the batch type pyrolysis recycling machine.

Different types waste tyre/plastic pyrolysis plants

The continuous type waste tire/plastic pyrolysis recycling machine is a new trend in the pyrolysis area, and Doing Company has sold many sets of continuous type pyrolysis recycling machines to different countries, such as China, Mexico, Spain, Kazakhstan, etc. The continuous type waste tire/plastic pyrolysis recycling machine is more suitable for relatively bigger scale projects, like 30t, 50t daily processing capacity and more. And it’s especially suitable for areas like Europe, America where labor costs are high.

Fully continuous waste tyre/plastic pyrolysis plant

And there are more and more governments guiding people to install the continuous type waste tire/plastic pyrolysis recycling machine because it has the advantages of high automation degree, pollution-free, labor and energy saving features. For example, India is the country whose government encourages to install the continuous type pyrolysis recycling machine, and the batch type machine is not allowed to be installed in many Indian states now.

The batch type waste tire/plastic pyrolysis recycling machine is also a popular option in developing countries for its cost-effective feature, especially in Africa, south Asia and South America. The technology of batch type pyrolysis recycling machine is relatively mature, and Doing has manufactured the batch type machine for over 12 years and sold these kinds of machines to over 90 countries.

Batch waste tyre/plastic pyrolysis plant

Relatively speaking, batch type waste tire/plastic pyrolysis recycling machine needs more labor to operate the plant than the continuous type machine, but it has relatively smaller investment and doesn’t need to pretreat the raw materials into specific state. Therefore, the batch type pyrolysis recycling machine is really suitable and cost effective for the small and regular scale pyrolysis plants with the daily processing capacity under 15t.

Whether you want to choose the continuous type or the batch type waste tire/plastic pyrolysis recycling machine, just feel free to contact Doing Company and tell us your plans, we can recommend the best solutions and customize the best waste tire/plastic pyrolysis recycling machine at factory price to you!