How does the overseas market change after China's "Forbidden Waste Order"?

Industry News / Chat on line / Give me a price / Date:2018-08-15

Waste plastic

Waste plastic

The United States is the world's largest producer of waste plastics. According to the United Nations Trade Statistics Database, in 2016 the United States exported nearly 4 million tons of waste plastics, 70% of which were exported to China.

Foreign garbage

Foreign garbage

How should the US handle a large amount of waste plastics after introducing the “Waste Waste Exemption Order” in China?

Several major problems facing waste plastics in countries including the United States:

Transportation cost

Environmental cost

Labor cost

How to cross, opportunities and challenges:

Recently, the US Senate passed the tax reform bill, which greatly reduced the burden on American companies and attracted overseas investment. More and more entrepreneurs tend to open factories in the United States, not to mention the quality of the workforce. The difficulty of corporate finance and the spirit of the entire social contract.

New technologies will be born under new demands. How to create new technology in the cost of waste plastics processing? Environmentally friendly processing technology, artificial intelligence? The United States and other countries affected by the Chinese plastic limit order have huge market space and unlimited opportunities.

DOING waste plastic pyrolysis palnt new technolygy to recycling the waste plastic

DOING waste plastic pyrolysis palnt new technolygy to recycling the waste plastic

At present, the consultation of waste plastics pyrolysis plant is very hot. In the countries affected by the Chinese plastic limit order, including the United States, the accumulation of thousands of tons of waste plastics in China has seriously affected people's quality of life, and the future environmental development is a huge threat.

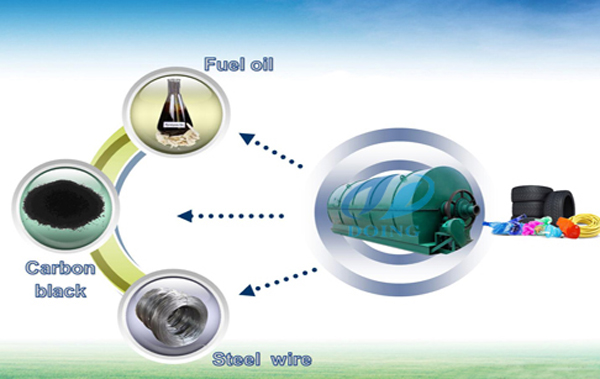

Waste plastic final products

Waste plastic final products

People began to look for new and effective technologies for dealing with waste plastics. DOING company's waste plastic pyrolysis plant can not only handle a large amount of accumulated waste plastics, but also solve the problem of thousands of tons of accumulated waste plastics. By running our waste plastic pyrolysis plant, we can also get fuel, carbon black and other materials that can be used to achieve economic benefits.

Batch and continuous pyrolysis plant show

Batch and continuous pyrolysis plant show

Among the customers who consulted our waste plastics pyrolysis plant, there are many relatively large projects contracted by the government. At this time, in addition to the above basic information, the customer is also very concerned about the processing capacity of the equipment. They are mainly worried that the daily processing capacity of our equipment cannot meet the requirements of them to process the large quantity of waste plastics. You don't need to worry about this at all. Our equipment is divided into intermittent and continuous waste plastic refining equipment. The intermittent waste plastic pyrolysis plant is mainly suitable for small and medium-sized workshops and refineries. The daily processing capacity of the equipment ranges from 3-12T. The throughput of continuous waste plastic pyrolysis palnt is relatively large, and it is mainly suitable for medium and large production workshops or refineries. The daily throughput of equipment ranges from 10-60T. If you have your own requirements for the amount of processing, it does not matter, tell us your specific needs, we have a team of professional engineers, will be specifically designed for you.

As China says "no" to "foreign garbage," it also "forces" the garbage recycling industry in the United States, Australia, Japan and other countries to "re-make a way out."

Adina Adler, senior director of the American Waste Recycling Industry Association, said that China's high standards and strict requirements are not all bad things for American companies. A horn of the garbage recycling revolution may have sounded.