A Thailand customer purchased a set of 18TPD waste tire pyrolysis machine

Enterprise News / Chat on line / Give me a price / Date:2023-08-10

Good news! On August 2, 2023, a Thailand customer purchased a set of 18TPD waste tire pyrolysis machine from DOING.

About the Thailand customer

The Thailand customer has engaged in waste tire pyrolysis business for over 20 years. With the continuous update of pyrolysis technology, the Thailand customer decided to purchase the newly designed waste tire pyrolysis machine to enhance its working performance and generate more profits. Then our sales manager made a detailed introduction about our waste tire pyrolysis machines from types, processing capacity to designing details, running videos. And in July, 2023, DOING also arranged a factory visit for the Thailand customer, who was satisfied with our waste tire pyrolysis machine. Especially during the machine operation, there is no bad smell and other pollution, such as dust pollution. Finally, the Thailand customer signed the contract with DOING.

The site picture of DOING factory

The site picture of DOING factory

About the waste tire pyrolysis machine

The waste tire pyrolysis machine purchased by the Thailand customer has a daily processing capacity of about 18 tons per batch, which can recycle waste tires to fuel oil, carbon black, steel wire and syn-gas to generate huge profits. The following are some advantages of the waste tire pyrolysis machine:

1. High oil yield

Our waste tire pyrolysis machine adopts the three-step cooling system, which has the industrial cooling effect to fully utilize oil gas and enhance oil yield; and our equipped buffer tank, vacuum negative pressure device can also avoid oil gas waste to improve oil yield.

Three-step cooling system of DOING waste tire pyrolysis machine

Three-step cooling system of DOING waste tire pyrolysis machine

2. Big processing capacity

Apart from the 18TPD waste tire pyrolysis machine purchased by the Thailand customer, we also have other capacities for your reference: 20/20/40/50+TPD, etc. And we can also provide the customization service based on your actual demand.

3. Environmentally friendly

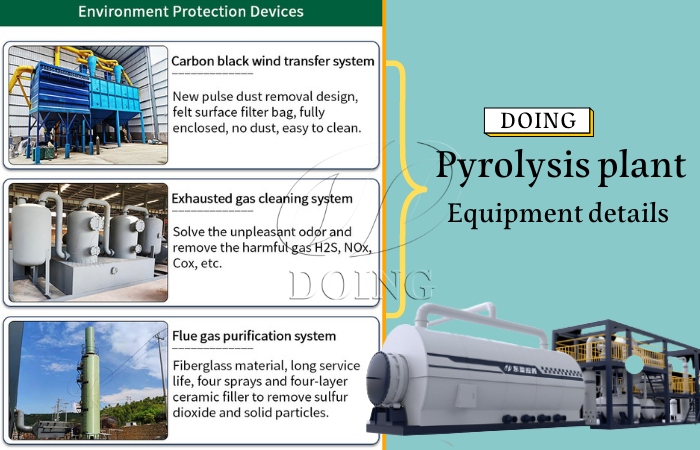

Our waste tire pyrolysis machine is equipped with some environmental protection systems: Tail gas cleaning system(purify the tail gas), Desulfurization tower(purify the smoke), Carbon black wind conveying system(avoid dust pollution), etc. And our cooling systems all adopted circulating water, producing no waste water pollution.

Environmental protection systems of DOING waste tire pyrolysis machine

Environmental protection systems of DOING waste tire pyrolysis machine

4. High safety

Our waste tire pyrolysis machine adopts some safety devices: Oil water seperator(prevent the back flow of oil gas), Water seal device(prevent the back flow of the tail gas), Vacuum negative pressure device(fully extract oil gas and keep safe operation pressure), etc.

Project cases of DOING waste tire pyrolysis machine

Project cases of DOING waste tire pyrolysis machine

The cooperation between the Thailand customer and DOING Company will promote the common development of both sides. Over the 13 years, DOING is committed to enhancing our pyrolysis technology to meet customers' various demands. If you are interested in waste tire pyrolysis machines or want to carry out other waste tire recycling projects, welcome to contact us, our sales manager can provide a detailed scheme for you.